CALGARY, Alberta — Canadian Pacific Kansas City said that 16 tentative collective bargaining agreements reached in recent weeks with various unions in the United States have all been ratified. All of the new, ratified five-year agreements provide increased wages to approximately 700 CPKC railroaders working in Illinois, Indiana, Louisiana, Minnesota, Mississippi, Missouri, New York, North Dakota, Oklahoma, Texas and Wisconsin. …One agreement has been reached and ratified with the Brotherhood of Locomotive Engineers and Trainmen (BLET) representing approximately 300 locomotive engineers on the Soo Line property operating trains in Illinois, Indiana, Minnesota, North Dakota and Wisconsin. Five agreements have been reached and ratified with the Brotherhood of Railway Carmen… Five agreements have been reached and ratified with the Transportation Communications Union (TCU/IAM) and American Railway and Airway Supervisors Association (ARASA)…

CALGARY, Alberta — Canadian Pacific Kansas City said that 16 tentative collective bargaining agreements reached in recent weeks with various unions in the United States have all been ratified. All of the new, ratified five-year agreements provide increased wages to approximately 700 CPKC railroaders working in Illinois, Indiana, Louisiana, Minnesota, Mississippi, Missouri, New York, North Dakota, Oklahoma, Texas and Wisconsin. …One agreement has been reached and ratified with the Brotherhood of Locomotive Engineers and Trainmen (BLET) representing approximately 300 locomotive engineers on the Soo Line property operating trains in Illinois, Indiana, Minnesota, North Dakota and Wisconsin. Five agreements have been reached and ratified with the Brotherhood of Railway Carmen… Five agreements have been reached and ratified with the Transportation Communications Union (TCU/IAM) and American Railway and Airway Supervisors Association (ARASA)…

MONTREAL, Quebec – Domtar announced a curtailment in its lumber production. Due to challenging market conditions, US tariffs, and ongoing economic uncertainty, the company will temporarily reduce its lumber production by 150 million board feet for the first quarter of 2026 across its facilities in Quebec, Ontario and the United States. “The demand for lumber in North America remains weak, requiring us to adjust our production levels in line with market conditions,” said Luc Thériault, CEO, Wood Products, and President – Canada, for Domtar. “While this decision is necessary, we are fully aware of the impact it will have on our employees, contractors, suppliers and the communities in which we operate.” Domtar will continue to monitor market conditions and adjust its production plans accordingly. Domtar has a workforce of nearly 14,000 employees in more than 60 locations across North America.

MONTREAL, Quebec – Domtar announced a curtailment in its lumber production. Due to challenging market conditions, US tariffs, and ongoing economic uncertainty, the company will temporarily reduce its lumber production by 150 million board feet for the first quarter of 2026 across its facilities in Quebec, Ontario and the United States. “The demand for lumber in North America remains weak, requiring us to adjust our production levels in line with market conditions,” said Luc Thériault, CEO, Wood Products, and President – Canada, for Domtar. “While this decision is necessary, we are fully aware of the impact it will have on our employees, contractors, suppliers and the communities in which we operate.” Domtar will continue to monitor market conditions and adjust its production plans accordingly. Domtar has a workforce of nearly 14,000 employees in more than 60 locations across North America. With the fate of North America’s free trade pact on the line, 2026 will be a significant year for some of Canada’s hardest-hit sectors in the trade war with the United States—including auto, steel, forestry and aluminum—as they advocate for Ottawa to do what’s necessary to preserve the deal, and to also help these sectors in the meantime by following through on domestic support measures. …Derek Nighbor, CEO of the Forest Products Association of Canada, said that Canada’s auto and forestry sectors are among the most highly-integrated with the US. While both sectors share this deep integration, Nighbor highlighted a critical distinction for forestry: unlike other industries, forestry facilities cannot be relocated to another country because the natural resource—the trees—remain in Canada. This comment comes amid heightened concerns regarding the 2026 CUSMA review and ongoing trade disputes, such as US softwood lumber tariffs. [to access the full story a Hill Times subscription is required]

With the fate of North America’s free trade pact on the line, 2026 will be a significant year for some of Canada’s hardest-hit sectors in the trade war with the United States—including auto, steel, forestry and aluminum—as they advocate for Ottawa to do what’s necessary to preserve the deal, and to also help these sectors in the meantime by following through on domestic support measures. …Derek Nighbor, CEO of the Forest Products Association of Canada, said that Canada’s auto and forestry sectors are among the most highly-integrated with the US. While both sectors share this deep integration, Nighbor highlighted a critical distinction for forestry: unlike other industries, forestry facilities cannot be relocated to another country because the natural resource—the trees—remain in Canada. This comment comes amid heightened concerns regarding the 2026 CUSMA review and ongoing trade disputes, such as US softwood lumber tariffs. [to access the full story a Hill Times subscription is required] VANCOUVER, BC — West Fraser Timber announced that it will record an impairment of its Lumber segment goodwill in the fourth quarter of 2025 due to persistently challenging economic conditions. The Company is also providing initial 2026 guidance for key product shipments, operational costs and capital expenditures. In Q4-2025, West Fraser expects to record an approximately $409 million non-cash impairment of goodwill as a result of the protracted downcycle that has caused management to recalibrate certain assumptions used in its annual goodwill impairment test. Adjustments to these assumptions include, but are not limited to, species-specific product pricing trends, lower demand and pricing for wood chip residuals, and the depth and duration of the current downcycle and its expected recovery. The impairment represents the entire amount of goodwill associated with the Company’s US lumber operations.

VANCOUVER, BC — West Fraser Timber announced that it will record an impairment of its Lumber segment goodwill in the fourth quarter of 2025 due to persistently challenging economic conditions. The Company is also providing initial 2026 guidance for key product shipments, operational costs and capital expenditures. In Q4-2025, West Fraser expects to record an approximately $409 million non-cash impairment of goodwill as a result of the protracted downcycle that has caused management to recalibrate certain assumptions used in its annual goodwill impairment test. Adjustments to these assumptions include, but are not limited to, species-specific product pricing trends, lower demand and pricing for wood chip residuals, and the depth and duration of the current downcycle and its expected recovery. The impairment represents the entire amount of goodwill associated with the Company’s US lumber operations. A new global risk assessment is warning that no country would be more “profoundly affected” by a political upheaval in the US than Canada. Published Monday, the Eurasia Group’s “

A new global risk assessment is warning that no country would be more “profoundly affected” by a political upheaval in the US than Canada. Published Monday, the Eurasia Group’s “ WASHINGTON — U.S. President Donald Trump said Tuesday the Canada-United States-Mexico Agreement on trade is “irrelevant” to him and Americans don’t need Canadian products. “It expires very shortly and we could have it or not,” Trump said while touring a Ford plant in Michigan. “It wouldn’t matter to me. I think they want it. I don’t really care about it.” Trump statements have rattled Canada and Mexico ahead of a mandatory review this year of the future of the continental trade pact, known as CUSMA. The president told reporters that “Canada wants it” but the United States doesn’t need anything from its northern neighbour. The three countries have started domestic consultations on the review and Dominic LeBlanc, the minister in charge of Canada-U.S. relations, is set to meet with U.S. counterparts in mid-January to launch formal CUSMA talks. The trade pact has shielded Canada and Mexico from the worst impacts of Trump’s tariffs.

WASHINGTON — U.S. President Donald Trump said Tuesday the Canada-United States-Mexico Agreement on trade is “irrelevant” to him and Americans don’t need Canadian products. “It expires very shortly and we could have it or not,” Trump said while touring a Ford plant in Michigan. “It wouldn’t matter to me. I think they want it. I don’t really care about it.” Trump statements have rattled Canada and Mexico ahead of a mandatory review this year of the future of the continental trade pact, known as CUSMA. The president told reporters that “Canada wants it” but the United States doesn’t need anything from its northern neighbour. The three countries have started domestic consultations on the review and Dominic LeBlanc, the minister in charge of Canada-U.S. relations, is set to meet with U.S. counterparts in mid-January to launch formal CUSMA talks. The trade pact has shielded Canada and Mexico from the worst impacts of Trump’s tariffs. The U.S. Endowment for Forestry and Communities has announced a new collaboration with the Georgia Institute of Technology to address the far-reaching social, economic and environmental impacts of pulp and paper mill closures across the United States, particularly in the rural South, where these mills have long served as economic anchors. The Endowment and Georgia Tech are developing an integrated decision-making dashboard to help policymakers, community leaders and industry stakeholders quantify the effects of mill closures and identify data-driven pathways to offset them through the sustainable use of forestry residues… Over the past decade, nearly 50 paper mills have shut down nationwide … resulting in the loss of thousands of jobs and disrupted local supply chains that once connected family forest owners, loggers, sawmills and manufacturers… As markets for timber and forestry byproducts contract, landowners face reduced incentives for active management – conditions that can increase the risk of wildfire, invasive species and forest conversion to other uses.

The U.S. Endowment for Forestry and Communities has announced a new collaboration with the Georgia Institute of Technology to address the far-reaching social, economic and environmental impacts of pulp and paper mill closures across the United States, particularly in the rural South, where these mills have long served as economic anchors. The Endowment and Georgia Tech are developing an integrated decision-making dashboard to help policymakers, community leaders and industry stakeholders quantify the effects of mill closures and identify data-driven pathways to offset them through the sustainable use of forestry residues… Over the past decade, nearly 50 paper mills have shut down nationwide … resulting in the loss of thousands of jobs and disrupted local supply chains that once connected family forest owners, loggers, sawmills and manufacturers… As markets for timber and forestry byproducts contract, landowners face reduced incentives for active management – conditions that can increase the risk of wildfire, invasive species and forest conversion to other uses.

Lumber futures rose toward $535 per thousand board feet, rebounding from the September low of $528 reached on January 7th after a low liquidity holiday sell off unwound, improving seasonal demand expectations and longer term supply tightening. Renewed engagement from market participants, signaled that forced selling and the thin trading conditions that pushed prices to multi month lows have faded. Seasonal demand expectations have strengthened as builders begin positioning ahead of the spring construction period, when consumption typically improves following year end destocking. Industry forecasts point to a modest pickup in US housing starts and repair and remodel activity in 2026 as interest rates ease and trade uncertainty recedes, supporting demand after a weak finish to 2025. At the same time, longer term supply growth remains constrained by ongoing tariffs on Canadian softwood and slower capacity expansion across North American sawmills, limiting surplus.

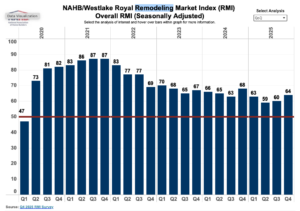

Lumber futures rose toward $535 per thousand board feet, rebounding from the September low of $528 reached on January 7th after a low liquidity holiday sell off unwound, improving seasonal demand expectations and longer term supply tightening. Renewed engagement from market participants, signaled that forced selling and the thin trading conditions that pushed prices to multi month lows have faded. Seasonal demand expectations have strengthened as builders begin positioning ahead of the spring construction period, when consumption typically improves following year end destocking. Industry forecasts point to a modest pickup in US housing starts and repair and remodel activity in 2026 as interest rates ease and trade uncertainty recedes, supporting demand after a weak finish to 2025. At the same time, longer term supply growth remains constrained by ongoing tariffs on Canadian softwood and slower capacity expansion across North American sawmills, limiting surplus. In the third quarter of 2025, the NAHB remodeling index (RMI) posted a reading of 64, increasing four points compared to the previous quarter. Most remodelers are finding reasonably strong market conditions, even with the normal seasonal slowdown during the holidays. The major headwinds the industry is experiencing continue to be rising costs and potential customers hesitating due to policy and economic uncertainty. Demand for remodeling is being supported by an aging housing stock, strong homeowner equity and increasing need for aging-in-place improvements. …In the fourth quarter of 2025, the Current Conditions Index averaged 71, increasing three points from the previous quarter. …The Future Indicators Index averaged 56, up four points from the previous quarter.

In the third quarter of 2025, the NAHB remodeling index (RMI) posted a reading of 64, increasing four points compared to the previous quarter. Most remodelers are finding reasonably strong market conditions, even with the normal seasonal slowdown during the holidays. The major headwinds the industry is experiencing continue to be rising costs and potential customers hesitating due to policy and economic uncertainty. Demand for remodeling is being supported by an aging housing stock, strong homeowner equity and increasing need for aging-in-place improvements. …In the fourth quarter of 2025, the Current Conditions Index averaged 71, increasing three points from the previous quarter. …The Future Indicators Index averaged 56, up four points from the previous quarter.

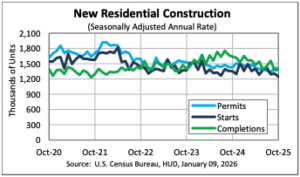

WASHINGTON — US single-family homebuilding rebounded in October, but permits for future construction eased, signaling caution among builders as new housing inventory remains high and demand soft. Single-family housing starts, which account for the bulk of homebuilding, increased 5.4% to a seasonally adjusted annual rate of 874,000 units in October, the Commerce Department’s Census Bureau said on Friday. Starts dropped to a pace of 829,000 units in September from a 869,000-unit pace in August. The reports were delayed by the 43-day government shutdown. …Permits for future single-family homebuilding fell 0.5% to a rate of 876,000 units in October. They increased to a pace of 880,000 units in September from a 858,000-unit rate in August.

WASHINGTON — US single-family homebuilding rebounded in October, but permits for future construction eased, signaling caution among builders as new housing inventory remains high and demand soft. Single-family housing starts, which account for the bulk of homebuilding, increased 5.4% to a seasonally adjusted annual rate of 874,000 units in October, the Commerce Department’s Census Bureau said on Friday. Starts dropped to a pace of 829,000 units in September from a 869,000-unit pace in August. The reports were delayed by the 43-day government shutdown. …Permits for future single-family homebuilding fell 0.5% to a rate of 876,000 units in October. They increased to a pace of 880,000 units in September from a 858,000-unit rate in August.

Toilet paper…is typically made with trees, energy-intensive manufacturing processes and chemicals that can pollute the environment. Experts say more consumers are seeking toilet paper made from recycled content or sustainable materials, but it can be hard to know what to look for. Sustainable toilet paper often costs more, but can have significant environmental benefits. According to the Environmental Paper Network, a coalition of nonprofits, more than 1 billion gallons of water and 1.6 million trees could be saved if every American used one roll of toilet paper made from recycled content instead of a roll made from forest fibres. Increasingly, manufacturers are making toilet paper from recycled paper products … using chlorine-free bleaching techniques. …Looking for recycled content is a good place for environmentally conscious consumers to start, said Gary Bull, at the University of British Columbia. Preconsumer materials include scrap materials from manufacturing or unsold paper. Postconsumer materials come from used paper products.

Toilet paper…is typically made with trees, energy-intensive manufacturing processes and chemicals that can pollute the environment. Experts say more consumers are seeking toilet paper made from recycled content or sustainable materials, but it can be hard to know what to look for. Sustainable toilet paper often costs more, but can have significant environmental benefits. According to the Environmental Paper Network, a coalition of nonprofits, more than 1 billion gallons of water and 1.6 million trees could be saved if every American used one roll of toilet paper made from recycled content instead of a roll made from forest fibres. Increasingly, manufacturers are making toilet paper from recycled paper products … using chlorine-free bleaching techniques. …Looking for recycled content is a good place for environmentally conscious consumers to start, said Gary Bull, at the University of British Columbia. Preconsumer materials include scrap materials from manufacturing or unsold paper. Postconsumer materials come from used paper products.

One year after wildfires tore through neighborhoods in Los Angeles County, killing at least 31 people and destroying more than 10,000 buildings, architects and developers are rethinking what home looks like in LA, and how resilient residential architecture evolves. …So far, hundreds of new homes have been submitted for permitting, but it’s a process shaping out to be an uneven one, based on damage, insurance and wealth. Affected homeowners are grappling with the details of fire-resilient construction and landscaping techniques, along with some more fundamental questions about what their communities should look like. …These 10 projects — all in various stages of completion — showcase several of the design concepts, construction techniques and development proposals in play as LA’s post-fire rebuilding process begins. …Many forthcoming home projects emphasize the latest in wildfire-resilience features: Think noncombustible sheathing and roof materials, triple-glazed windows that can resist high heat, and defensible outdoor space.

One year after wildfires tore through neighborhoods in Los Angeles County, killing at least 31 people and destroying more than 10,000 buildings, architects and developers are rethinking what home looks like in LA, and how resilient residential architecture evolves. …So far, hundreds of new homes have been submitted for permitting, but it’s a process shaping out to be an uneven one, based on damage, insurance and wealth. Affected homeowners are grappling with the details of fire-resilient construction and landscaping techniques, along with some more fundamental questions about what their communities should look like. …These 10 projects — all in various stages of completion — showcase several of the design concepts, construction techniques and development proposals in play as LA’s post-fire rebuilding process begins. …Many forthcoming home projects emphasize the latest in wildfire-resilience features: Think noncombustible sheathing and roof materials, triple-glazed windows that can resist high heat, and defensible outdoor space.

PORTLAND, Ore. — In a win for conservation groups, a federal judge

PORTLAND, Ore. — In a win for conservation groups, a federal judge  Western Washington forests are vital to the identity, economy, and quality of life vital to the region. From the Puget Sound to the Olympic Peninsula and Columbia Gorge, healthy forests provide clean air and water, sustain fish and wildlife habitat, store carbon, and support local jobs in forestry, recreation, and tourism. …The Western Washington Forest Health Strategic Plan is the result of an holistic and collaborative effort by the Washington State Department of Natural Resources to bring partners representing all lands and stakeholder groups together to identify priorities and strategies for how to steward and manage western Washington forests at a landscape scale. This plan builds on lessons learned from the development and implementation of the

Western Washington forests are vital to the identity, economy, and quality of life vital to the region. From the Puget Sound to the Olympic Peninsula and Columbia Gorge, healthy forests provide clean air and water, sustain fish and wildlife habitat, store carbon, and support local jobs in forestry, recreation, and tourism. …The Western Washington Forest Health Strategic Plan is the result of an holistic and collaborative effort by the Washington State Department of Natural Resources to bring partners representing all lands and stakeholder groups together to identify priorities and strategies for how to steward and manage western Washington forests at a landscape scale. This plan builds on lessons learned from the development and implementation of the  PUEBLO, Colo. — The Pike-San Isabel National Forests & Cimarron and Comanche National Grasslands began a 10-year partnership and $7.3 million investment to implement forest health treatments as part of the War Department’s Readiness and Environmental Protection Integration (REPI) program. The partners will use $3 million in REPI funds, along with $4.3 million in partner contributions, to treat 2,000 acres of National Forest System land and nonfederal lands near the U.S. Air Force Academy and Cheyenne Mountain Space Force Station. The REPI program preserves military missions by avoiding land use conflicts near military installations, addressing environmental restrictions that limit military activities and increasing military installation resilience.

PUEBLO, Colo. — The Pike-San Isabel National Forests & Cimarron and Comanche National Grasslands began a 10-year partnership and $7.3 million investment to implement forest health treatments as part of the War Department’s Readiness and Environmental Protection Integration (REPI) program. The partners will use $3 million in REPI funds, along with $4.3 million in partner contributions, to treat 2,000 acres of National Forest System land and nonfederal lands near the U.S. Air Force Academy and Cheyenne Mountain Space Force Station. The REPI program preserves military missions by avoiding land use conflicts near military installations, addressing environmental restrictions that limit military activities and increasing military installation resilience.  As climate change drives more frequent and severe wildfires across boreal forests in Alaska and northwestern Canada, scientists are asking a critical question: Will these ecosystems continue to store carbon or become a growing source of carbon emissions? New research published shows that when forests shift from coniferous—consisting mostly of pines, spruces and larches—to deciduous—consisting mostly of birches and aspens—they could release substantially less carbon when they burn. The study, led by researchers from the Center for Ecosystem Science and Society (ECOSS) at Northern Arizona University and published in Nature Climate Change, found that boreal forests dominated by deciduous species lose less than half as much carbon per unit area burned compared to historically dominant black spruce forests. Even under severe fire weather conditions, carbon losses in deciduous stands were consistently lower than those in conifer forests.

As climate change drives more frequent and severe wildfires across boreal forests in Alaska and northwestern Canada, scientists are asking a critical question: Will these ecosystems continue to store carbon or become a growing source of carbon emissions? New research published shows that when forests shift from coniferous—consisting mostly of pines, spruces and larches—to deciduous—consisting mostly of birches and aspens—they could release substantially less carbon when they burn. The study, led by researchers from the Center for Ecosystem Science and Society (ECOSS) at Northern Arizona University and published in Nature Climate Change, found that boreal forests dominated by deciduous species lose less than half as much carbon per unit area burned compared to historically dominant black spruce forests. Even under severe fire weather conditions, carbon losses in deciduous stands were consistently lower than those in conifer forests.

SEATTLE — Twenty-five years ago, I stood in a snowy National Arboretum in Washington, DC, shaking hands with President Bill Clinton at the signing ceremony for the most important forest conservation mandate in our country’s history. But now that landmark law, which went into effect on Jan. 12, 2001, is hanging by a thread, marked for repeal by the Trump administration — even though 99% of citizen input opposes the idea. The “Roadless Rule” was adopted to curtail harmful logging and industrial roadbuilding across 58 million undeveloped acres of our national forests. More than 2 million acres of those wild lands are in Washington, helping keep this the Evergreen State. …Trump officials claim that opening these areas to bulldozers and chain saws will protect communities from wildfire. But that’s a story that just doesn’t wash. [to access the full story a Seattle Times subscription is required]

SEATTLE — Twenty-five years ago, I stood in a snowy National Arboretum in Washington, DC, shaking hands with President Bill Clinton at the signing ceremony for the most important forest conservation mandate in our country’s history. But now that landmark law, which went into effect on Jan. 12, 2001, is hanging by a thread, marked for repeal by the Trump administration — even though 99% of citizen input opposes the idea. The “Roadless Rule” was adopted to curtail harmful logging and industrial roadbuilding across 58 million undeveloped acres of our national forests. More than 2 million acres of those wild lands are in Washington, helping keep this the Evergreen State. …Trump officials claim that opening these areas to bulldozers and chain saws will protect communities from wildfire. But that’s a story that just doesn’t wash. [to access the full story a Seattle Times subscription is required]

VALLEJO, Calif. — The USDA Forest Service Pacific Southwest Region and CAL FIRE have renewed their commitment to battling wildfires across California. This renewal extends the California Fire Master Agreement for another five years. The agreement, signed by Pacific Southwest interim Regional Forester Jacque Buchanan and CAL FIRE Chief Joe Tyler on Dec. 12, allows for a cooperative approach to wildfire response. According to the USDA Forest Service, this collaboration enables firefighters to share resources and respond across jurisdictional lines during emergencies. “This complex operating environment within California and the challenges we face year-round require this collaborative approach,” Jaime Gamboa, fire director for the Forest Service’s Pacific Southwest Region, said. The agreement emphasizes a united front in wildfire emergencies, prioritizing the closest available resources to protect lives and property. It also covers hazardous fuels reduction and streamlines training and equipment sharing.

VALLEJO, Calif. — The USDA Forest Service Pacific Southwest Region and CAL FIRE have renewed their commitment to battling wildfires across California. This renewal extends the California Fire Master Agreement for another five years. The agreement, signed by Pacific Southwest interim Regional Forester Jacque Buchanan and CAL FIRE Chief Joe Tyler on Dec. 12, allows for a cooperative approach to wildfire response. According to the USDA Forest Service, this collaboration enables firefighters to share resources and respond across jurisdictional lines during emergencies. “This complex operating environment within California and the challenges we face year-round require this collaborative approach,” Jaime Gamboa, fire director for the Forest Service’s Pacific Southwest Region, said. The agreement emphasizes a united front in wildfire emergencies, prioritizing the closest available resources to protect lives and property. It also covers hazardous fuels reduction and streamlines training and equipment sharing.

President Donald Trump’s administration has set in motion efforts to repeal the Roadless Rule, a 2001 administrative mandate that put 45 million acres of the least developed forest land under protection from logging and construction of roads. As the nation observes the rule’s 25th anniversary, Virginia’s federal lawmakers and advocates are calling for its preservation and say hundreds of thousands of acres of forests could be at stake if it is axed. The federal government has framed the proposed repeal as necessary for forest management against wildfires. …Environmental advocates have said since last summer that repealing the rule will lead to land degradation, sediment pollution, and create risks to clean water sources. It would also open up large swaths of the 400,000 acres of the protected forestland in Virginia to logging and potential new roads.

President Donald Trump’s administration has set in motion efforts to repeal the Roadless Rule, a 2001 administrative mandate that put 45 million acres of the least developed forest land under protection from logging and construction of roads. As the nation observes the rule’s 25th anniversary, Virginia’s federal lawmakers and advocates are calling for its preservation and say hundreds of thousands of acres of forests could be at stake if it is axed. The federal government has framed the proposed repeal as necessary for forest management against wildfires. …Environmental advocates have said since last summer that repealing the rule will lead to land degradation, sediment pollution, and create risks to clean water sources. It would also open up large swaths of the 400,000 acres of the protected forestland in Virginia to logging and potential new roads.

When UN Spokesperson Stéphane Dujarric briefed correspondents in New York on Thursday following the release of the White House Memorandum, he insisted that the Organization will continue to carry out its mandates from Member States “with determination.” Wednesday’s memorandum states that the US administration is “ceasing participation in or funding to those entities to the extent permitted by law.” Several of the bodies listed in the memo are funded principally or partially by the regular UN budget, implying that voluntary funding will be impacted, although central funding will continue. However, the White House notes that its funding review of international organisations “remains ongoing,” and it is currently unclear what the impact of the announcement will be. Here’s a breakdown of the 31 UN entities mentioned in the memorandum, and how they are making a positive difference to people, communities and nations, worldwide.

When UN Spokesperson Stéphane Dujarric briefed correspondents in New York on Thursday following the release of the White House Memorandum, he insisted that the Organization will continue to carry out its mandates from Member States “with determination.” Wednesday’s memorandum states that the US administration is “ceasing participation in or funding to those entities to the extent permitted by law.” Several of the bodies listed in the memo are funded principally or partially by the regular UN budget, implying that voluntary funding will be impacted, although central funding will continue. However, the White House notes that its funding review of international organisations “remains ongoing,” and it is currently unclear what the impact of the announcement will be. Here’s a breakdown of the 31 UN entities mentioned in the memorandum, and how they are making a positive difference to people, communities and nations, worldwide.