Visit Canada Wood’s Market News for these stories and more:

Visit Canada Wood’s Market News for these stories and more:

- BC advanced its international wood promotion efforts on several fronts this month. Premier David Eby and Jobs Minister Ravi Kahlon led a trade mission to India under the Province’s Look West Strategy, highlighting B.C.’s leadership in sustainable forestry and wood products as part of efforts to diversify export markets.

- Meanwhile, Canada Wood co-sponsored a seven-day tour for eighteen senior members of the Japan 2×4 Home Builders Association to mark the association’s 50th anniversary. The delegation visited Edmonton and Vancouver to strengthen industry ties and explore advances in wood construction.

- Japan is preparing to introduce a national Life Cycle Assessment framework by 2028 that will measure whole-building carbon impacts—an approach expected to favour wood materials. Even Expo 2025’s iconic Grand Ring will be dismantled and reused under a circular-market program.

- Despite a 6.5% drop in 2025 Japan’s housing starts, wood increased its market share to 58.6%, with gains in both residential and non-residential construction.

As Denmark has recently tightened its standards for new construction with the aim of reducing embodied carbon, what lessons can Canada draw from this experience? In 2023, the Danish Building Code made life-cycle assessment (LCA) mandatory for all new buildings over their first fifty years. …The government also mandated researchers to provide practitioners with a list of generic material data for cases where an Environmental Product Declaration (EPD)—required to perform an LCA. When the regulation came into force in 2023, the entire construction industry was opposed to it, recalls Thomas Graabaek. “ And then slowly there was a movement within architects and engineers that actually we need to have even stricter demands.” …“Unfortunately, in Canada, [architects] have been educated only around operations, [not on its entire life cycle],” explains Kelly Alvarez Doran. He advocates for the establishment of embodied-carbon targets at different regulatory scales.

As Denmark has recently tightened its standards for new construction with the aim of reducing embodied carbon, what lessons can Canada draw from this experience? In 2023, the Danish Building Code made life-cycle assessment (LCA) mandatory for all new buildings over their first fifty years. …The government also mandated researchers to provide practitioners with a list of generic material data for cases where an Environmental Product Declaration (EPD)—required to perform an LCA. When the regulation came into force in 2023, the entire construction industry was opposed to it, recalls Thomas Graabaek. “ And then slowly there was a movement within architects and engineers that actually we need to have even stricter demands.” …“Unfortunately, in Canada, [architects] have been educated only around operations, [not on its entire life cycle],” explains Kelly Alvarez Doran. He advocates for the establishment of embodied-carbon targets at different regulatory scales.

Canada Wood’s January market news highlights the continued expansion of Canadian wood products into key international markets, with a strong focus on mass timber, technical innovation, and long-term partnerships. Articles explore new opportunities for Canadian species in China’s growing glulam sector, including efforts to diversify beyond Douglas fir into Hem-Fir, SPF, and yellow cedar. Other features examine rising interest in mass timber construction in South Korea, driven by carbon-reduction goals and modern architectural demand. The January updates also showcase how long-standing Canadian demonstration projects in southern China are building confidence in wood’s durability in challenging climates, helping pave the way for larger, more complex structures. Rounding out the month is news of renewed Canada–China cooperation on wood construction, reinforcing shared commitments to low-carbon building and sustainable urban development. Together, these stories offer a timely snapshot of how Canadian wood expertise is shaping construction practices abroad.

Canada Wood’s January market news highlights the continued expansion of Canadian wood products into key international markets, with a strong focus on mass timber, technical innovation, and long-term partnerships. Articles explore new opportunities for Canadian species in China’s growing glulam sector, including efforts to diversify beyond Douglas fir into Hem-Fir, SPF, and yellow cedar. Other features examine rising interest in mass timber construction in South Korea, driven by carbon-reduction goals and modern architectural demand. The January updates also showcase how long-standing Canadian demonstration projects in southern China are building confidence in wood’s durability in challenging climates, helping pave the way for larger, more complex structures. Rounding out the month is news of renewed Canada–China cooperation on wood construction, reinforcing shared commitments to low-carbon building and sustainable urban development. Together, these stories offer a timely snapshot of how Canadian wood expertise is shaping construction practices abroad. VANCOUVER — UBC’s newest building, Gateway Health, is opening as a hub for student health, interdisciplinary teaching and collaborative research. The 270,550-square-foot building gives a purpose-built home to the school of nursing, consolidates kinesiology programs from eight campus locations, and centralizes student health and wellbeing services for the first time. …

VANCOUVER — UBC’s newest building, Gateway Health, is opening as a hub for student health, interdisciplinary teaching and collaborative research. The 270,550-square-foot building gives a purpose-built home to the school of nursing, consolidates kinesiology programs from eight campus locations, and centralizes student health and wellbeing services for the first time. …

Zoom Webinar | Wednesday, February 25, 2026 | 10:00am – 11:30am PST | Zoom. BC’s wood manufacturers are facing real challenges from labour shortages and export pressures to rising costs and growing sustainability expectations. The good news? There’s funding available to support your hiring, workforce development, technology upgrades, product innovation, and market expansion. Join this session designed specifically for processors, builders, and related businesses in the value-added wood sector. You’ll learn how to use grants strategically, not reactively, to achieve your business goals. What you will learn:

Zoom Webinar | Wednesday, February 25, 2026 | 10:00am – 11:30am PST | Zoom. BC’s wood manufacturers are facing real challenges from labour shortages and export pressures to rising costs and growing sustainability expectations. The good news? There’s funding available to support your hiring, workforce development, technology upgrades, product innovation, and market expansion. Join this session designed specifically for processors, builders, and related businesses in the value-added wood sector. You’ll learn how to use grants strategically, not reactively, to achieve your business goals. What you will learn: Modern Methods of Construction Education (MMC Edu) is a national platform that connects education and industry to advance construction training in Canada. It is a key outcome of the Mass Timber Training Network: Advancing Trades for a Sustainable Future (MTAT) project, which brings together a national network to advance wood as a low-carbon building material by addressing major barriers to mass timber adoption across the country. Led by the British Columbia Institute of Technology (BCIT) in partnership with Natural Resources Canada (NRCan) through the Green Construction Through Wood Program (GC Wood), the MTAT project focuses on education and training as a key vehicle for reducing barriers and preparing the next generation of the workforce. MMC Edu serves as a shared platform where network members, industry partners, and educators can exchange knowledge and access resources that support innovation, sustainability, and workforce readiness across Canada.

Modern Methods of Construction Education (MMC Edu) is a national platform that connects education and industry to advance construction training in Canada. It is a key outcome of the Mass Timber Training Network: Advancing Trades for a Sustainable Future (MTAT) project, which brings together a national network to advance wood as a low-carbon building material by addressing major barriers to mass timber adoption across the country. Led by the British Columbia Institute of Technology (BCIT) in partnership with Natural Resources Canada (NRCan) through the Green Construction Through Wood Program (GC Wood), the MTAT project focuses on education and training as a key vehicle for reducing barriers and preparing the next generation of the workforce. MMC Edu serves as a shared platform where network members, industry partners, and educators can exchange knowledge and access resources that support innovation, sustainability, and workforce readiness across Canada. International Pulp Week (IPW) is the premier annual gathering for the global market pulp sector, organized by the Pulp and Paper Products Council (PPPC). Set for May 10–12, 2026 at the Sutton Place Hotel in Vancouver, BC, the three-day conference brings together producers, customers, logistics providers, analysts and other key stakeholders from around the world to share market intelligence, expert insights and strategic dialogue on trends shaping the future of pulp markets. Through keynote presentations, expert panels and extensive networking opportunities, IPW offers decision-makers high-value analysis, opportunities for business development, and collaboration across the pulp supply chain. The event has become a must-attend forum for those involved in international pulp production, trade and investment, with participants from more than 40 countries expected to attend.

International Pulp Week (IPW) is the premier annual gathering for the global market pulp sector, organized by the Pulp and Paper Products Council (PPPC). Set for May 10–12, 2026 at the Sutton Place Hotel in Vancouver, BC, the three-day conference brings together producers, customers, logistics providers, analysts and other key stakeholders from around the world to share market intelligence, expert insights and strategic dialogue on trends shaping the future of pulp markets. Through keynote presentations, expert panels and extensive networking opportunities, IPW offers decision-makers high-value analysis, opportunities for business development, and collaboration across the pulp supply chain. The event has become a must-attend forum for those involved in international pulp production, trade and investment, with participants from more than 40 countries expected to attend.

The Wood Innovations Funding Opportunity supports the growth and expansion of U.S. wood products and wood energy markets, advancing sustainable forest management and the long-term stewardship of National Forest System (NFS) lands and other forested areas. …The Wood Innovations Funding Opportunity provides a strategic platform for public, private, and non-profit entities to expand wood markets, promote sustainable forest management, and advance wood energy and mass timber technologies across the United States. By funding projects that create tangible economic and environmental impact, the program strengthens domestic wood product industries while supporting the responsible management of forest resources. Deadline is April 22, 2026

The Wood Innovations Funding Opportunity supports the growth and expansion of U.S. wood products and wood energy markets, advancing sustainable forest management and the long-term stewardship of National Forest System (NFS) lands and other forested areas. …The Wood Innovations Funding Opportunity provides a strategic platform for public, private, and non-profit entities to expand wood markets, promote sustainable forest management, and advance wood energy and mass timber technologies across the United States. By funding projects that create tangible economic and environmental impact, the program strengthens domestic wood product industries while supporting the responsible management of forest resources. Deadline is April 22, 2026

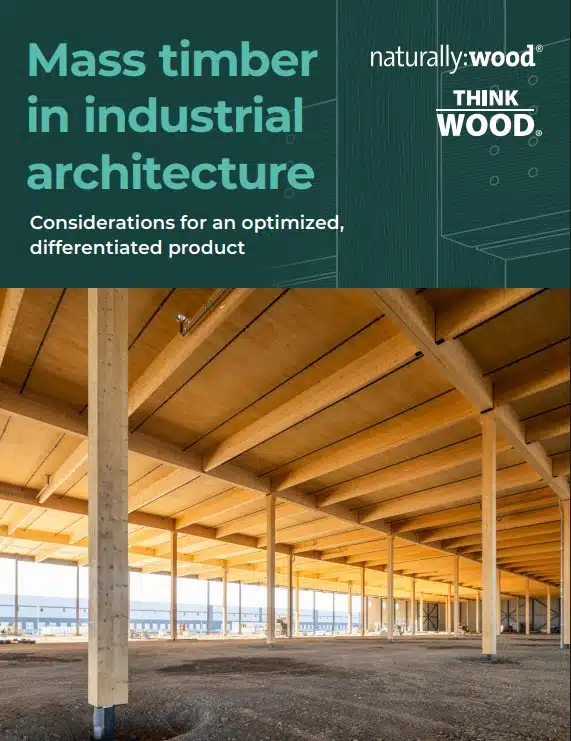

As mass timber continues to grow in popularity in the US, manufacturers are evolving the scale and sourcing of wood production to meet rising demand.

As mass timber continues to grow in popularity in the US, manufacturers are evolving the scale and sourcing of wood production to meet rising demand.

MESA COUNTY, Colorado. – Mesa County commissioners have passed a wildfire resiliency code that will affect the construction of new houses and projects on current structures, including re-roofing. The code, required by state legislation, applies only to buildings in the Wildland Urban Interface — a designated area marking locations close to potential wildfires. It mandates that projects in those areas use more fire-resistant materials and regulates where new structures can be built. “It’s not going to keep houses from burning down…,” Davis said. “What it’s designed to do is to keep it from burning as quick and as violently so that people can get out and get to safety.” Davis said the new code could make building in affected areas slower and more expensive. “To make things fire resistant, it costs money. The cheapest siding out there is wood-based and more affordable, but it’s also going to be more flammable,” Davis said.

MESA COUNTY, Colorado. – Mesa County commissioners have passed a wildfire resiliency code that will affect the construction of new houses and projects on current structures, including re-roofing. The code, required by state legislation, applies only to buildings in the Wildland Urban Interface — a designated area marking locations close to potential wildfires. It mandates that projects in those areas use more fire-resistant materials and regulates where new structures can be built. “It’s not going to keep houses from burning down…,” Davis said. “What it’s designed to do is to keep it from burning as quick and as violently so that people can get out and get to safety.” Davis said the new code could make building in affected areas slower and more expensive. “To make things fire resistant, it costs money. The cheapest siding out there is wood-based and more affordable, but it’s also going to be more flammable,” Davis said.

Building homes inside a factory has long been seen as a way to revolutionize the American housing industry, ushering in a new era of higher quality homes at lower price. That dream has never quite panned out. Can California finally make it happen? …For decades engineers, architects, futurists, industrialists, investors and politicians have been pining for a better, faster and cheaper way to build homes. Now, amid a national housing shortage, the question felt as pressing as ever: What if construction could harness the speed, efficiency, quality control and cost-savings of the assembly line? …What if the United States could mass-produce its way out of a housing crisis? …This year, state legislators in California believe the turning-point might actually be here. With a little state assistance, they want to make 2026 the Year of the Housing Factory. At long last.

Building homes inside a factory has long been seen as a way to revolutionize the American housing industry, ushering in a new era of higher quality homes at lower price. That dream has never quite panned out. Can California finally make it happen? …For decades engineers, architects, futurists, industrialists, investors and politicians have been pining for a better, faster and cheaper way to build homes. Now, amid a national housing shortage, the question felt as pressing as ever: What if construction could harness the speed, efficiency, quality control and cost-savings of the assembly line? …What if the United States could mass-produce its way out of a housing crisis? …This year, state legislators in California believe the turning-point might actually be here. With a little state assistance, they want to make 2026 the Year of the Housing Factory. At long last.  The Berkeley Wood Lab’s research on mass timber production has the potential to improve California’s sustainability by sourcing from local forests. The lab is collaborating with Northern Californian lumber company Mad River Mass Timber, or MRMT. The company will use Californian trees that otherwise would have either been turned into woodchips or burned in a forest fire to build panels that can be used in new housing and commercial buildings. This is the first time these types of panels will be produced locally in California instead of being shipped in from other countries. The technology to create dowel-laminated timber, or DLT, has existed for decades, but the Berkeley Wood Lab adapted it for use in Californian forests. Through the process of making DLT, glue is not required, which enables the timber to be recycled in the future and turned into new material.

The Berkeley Wood Lab’s research on mass timber production has the potential to improve California’s sustainability by sourcing from local forests. The lab is collaborating with Northern Californian lumber company Mad River Mass Timber, or MRMT. The company will use Californian trees that otherwise would have either been turned into woodchips or burned in a forest fire to build panels that can be used in new housing and commercial buildings. This is the first time these types of panels will be produced locally in California instead of being shipped in from other countries. The technology to create dowel-laminated timber, or DLT, has existed for decades, but the Berkeley Wood Lab adapted it for use in Californian forests. Through the process of making DLT, glue is not required, which enables the timber to be recycled in the future and turned into new material.

The mass timber supply chain has spent more than a decade proving the product works. …Now, research produced by Michigan State University argues that none of it matters much if the system surrounding the product isn’t built to match. Led by George Berghorn, Modular Mass Timber for Housing Construction, research published in the

The mass timber supply chain has spent more than a decade proving the product works. …Now, research produced by Michigan State University argues that none of it matters much if the system surrounding the product isn’t built to match. Led by George Berghorn, Modular Mass Timber for Housing Construction, research published in the  Since International Paper closed its mills in Liberty and Chatham counties last fall, business owners in Southeast Georgia who once made the state the largest timber exporter in the nation have been feeling acute pain. As of January, demand for timber had dropped more than 60%. …The cost of pulpwood, meanwhile, had plummeted. …Gov. Brian Kemp has carved $14 million for the timber industry in his draft budget, based on recommendations from a

Since International Paper closed its mills in Liberty and Chatham counties last fall, business owners in Southeast Georgia who once made the state the largest timber exporter in the nation have been feeling acute pain. As of January, demand for timber had dropped more than 60%. …The cost of pulpwood, meanwhile, had plummeted. …Gov. Brian Kemp has carved $14 million for the timber industry in his draft budget, based on recommendations from a  Massachusetts is considering changing state building codes to allow single staircases in multi-family residential buildings up to six stories. Advocates say the change would result in smaller buildings, space savings that could lead to 130,000 new housing units. Before changing the building codes, which currently require two exit stairways, Massachusetts Governor Maura Healey has signed an executive order establishing a technical advisory panel to study potential safety issues. “We’re all about making it easier to build more housing across our state to drive down costs for everyone,” Healey said in a statement. “While the double-stair requirement plays an important role in ensuring safety, it’s also holding us back from the type of housing construction we need to meet demand.” …New York City and Seattle, Washington have “permitted single-stair buildings up to six stories for decades,” the administration says…, as have the states of Tennessee, Montana, and Connecticut.

Massachusetts is considering changing state building codes to allow single staircases in multi-family residential buildings up to six stories. Advocates say the change would result in smaller buildings, space savings that could lead to 130,000 new housing units. Before changing the building codes, which currently require two exit stairways, Massachusetts Governor Maura Healey has signed an executive order establishing a technical advisory panel to study potential safety issues. “We’re all about making it easier to build more housing across our state to drive down costs for everyone,” Healey said in a statement. “While the double-stair requirement plays an important role in ensuring safety, it’s also holding us back from the type of housing construction we need to meet demand.” …New York City and Seattle, Washington have “permitted single-stair buildings up to six stories for decades,” the administration says…, as have the states of Tennessee, Montana, and Connecticut.

.jpg)

BHUBANESWAR: India should explore inclusion of wood-based construction and buildings into the national building code to achieve optimal outcomes for climate change and the economy, opined experts at the 14th National Workshop of Japan International Cooperation Agency Assisted Forestry Projects. The three-day workshop is organised by the Odisha Forestry Sector Development Project focuses on strengthening sustainable wood supply systems, promoting forest certification and expanding agroforestry to meet both domestic and global demands. Odisha Forestry Sector Development Society officials said while the National Building Code of India advocates bamboo for use in construction … international experts at the workshop opined that production and use of wood-based and other natural construction materials can also be explored to reduce dependence on carbon-intensive materials further and encourage sustainable forestry.

BHUBANESWAR: India should explore inclusion of wood-based construction and buildings into the national building code to achieve optimal outcomes for climate change and the economy, opined experts at the 14th National Workshop of Japan International Cooperation Agency Assisted Forestry Projects. The three-day workshop is organised by the Odisha Forestry Sector Development Project focuses on strengthening sustainable wood supply systems, promoting forest certification and expanding agroforestry to meet both domestic and global demands. Odisha Forestry Sector Development Society officials said while the National Building Code of India advocates bamboo for use in construction … international experts at the workshop opined that production and use of wood-based and other natural construction materials can also be explored to reduce dependence on carbon-intensive materials further and encourage sustainable forestry. At COP 30 in Belém, Brazil, the 2025 United Nations climate conference was widely seen as an “implementation COP”. …Here, USGBC shares concrete initiatives from COP 30 for a people-centered transition of the buildings sector and what will shape the agenda in 2026. …Public procurement and low-carbon construction – The ICBC adopted a Global Framework for Action on Sustainable Procurement, recognizing that public spending, around 13–20% of GDP, can serve as a strategic lever to create demand for low-carbon construction materials and practices. By leveraging the purchasing power of national and local governments, policymakers can send the long-term market signals needed to shift the construction sector toward net zero, given that construction and infrastructure together account for the largest share of public authority budgets. Ministers and over 300 stakeholders also endorsed the Principles for Responsible Timber Construction, promoting bio-based, circular building practices and ensuring the sustainable management of wood resources as demand grows.

At COP 30 in Belém, Brazil, the 2025 United Nations climate conference was widely seen as an “implementation COP”. …Here, USGBC shares concrete initiatives from COP 30 for a people-centered transition of the buildings sector and what will shape the agenda in 2026. …Public procurement and low-carbon construction – The ICBC adopted a Global Framework for Action on Sustainable Procurement, recognizing that public spending, around 13–20% of GDP, can serve as a strategic lever to create demand for low-carbon construction materials and practices. By leveraging the purchasing power of national and local governments, policymakers can send the long-term market signals needed to shift the construction sector toward net zero, given that construction and infrastructure together account for the largest share of public authority budgets. Ministers and over 300 stakeholders also endorsed the Principles for Responsible Timber Construction, promoting bio-based, circular building practices and ensuring the sustainable management of wood resources as demand grows.