Most researchers today explore high-tech materials like carbon nanotubes or graphene to develop a class of composite known as radar-absorbing material, i.e., a composite that can attenuate radar signals for stealth applications. Such high-tech materials are costly and energy-intensive to produce. Researchers from Brazil and Canada have explored sustainable carbon made of tree bark waste as an affordable alternative to those options. Their findings were recently published in the Journal of Renewable Materials, with insights on how engineering material and design can lead to performances as well as those expensive options. The research also supports the goals of the United Nations’ 2030 Agenda for Sustainable Development, by promoting the use of renewable materials and reducing industrial waste. The team plans to scale up production and test the core material in other real-world situations.

Most researchers today explore high-tech materials like carbon nanotubes or graphene to develop a class of composite known as radar-absorbing material, i.e., a composite that can attenuate radar signals for stealth applications. Such high-tech materials are costly and energy-intensive to produce. Researchers from Brazil and Canada have explored sustainable carbon made of tree bark waste as an affordable alternative to those options. Their findings were recently published in the Journal of Renewable Materials, with insights on how engineering material and design can lead to performances as well as those expensive options. The research also supports the goals of the United Nations’ 2030 Agenda for Sustainable Development, by promoting the use of renewable materials and reducing industrial waste. The team plans to scale up production and test the core material in other real-world situations.

Kalesnikoff Mass Timber recently opened its new 100,000-square-foot mass timber prefabrication and modular facility in Castlegar, B.C., 400 miles east of Vancouver. Starting small just before the Second World War, Kalesnikoff today is a family-owned, fourth-generation company that produces dimensional lumber, glulam beams and columns, glue-laminated timber (GLT) panels, cross laminated timber (CLT) and prefabricated components. The new facility, which is built entirely out of Kalesnikoff’s own mass timber… enables Kalesnikoff to provide new products that can be used for prefabricated walls, flooring, modules and full modular construction. Chief operating officer Chris Kalesnikoff says it’s the first vertically integrated mass timber operation in North America. Kalesnikoff was started by Chris’s great-grandfather and two of his brothers in 1939 as a logging operation. His grandfather and his father (Ken) expanded the sawmill into value-added wood products.

Kalesnikoff Mass Timber recently opened its new 100,000-square-foot mass timber prefabrication and modular facility in Castlegar, B.C., 400 miles east of Vancouver. Starting small just before the Second World War, Kalesnikoff today is a family-owned, fourth-generation company that produces dimensional lumber, glulam beams and columns, glue-laminated timber (GLT) panels, cross laminated timber (CLT) and prefabricated components. The new facility, which is built entirely out of Kalesnikoff’s own mass timber… enables Kalesnikoff to provide new products that can be used for prefabricated walls, flooring, modules and full modular construction. Chief operating officer Chris Kalesnikoff says it’s the first vertically integrated mass timber operation in North America. Kalesnikoff was started by Chris’s great-grandfather and two of his brothers in 1939 as a logging operation. His grandfather and his father (Ken) expanded the sawmill into value-added wood products.

The Kelowna International Airport (YLW) is proud to share a significant project milestone for Airport Terminal Building (ATB) expansion – the mass timber roof structure of the facility is now complete. The use of mass timber throughout the terminal building expansion highlights the airport’s commitment to sustainability, innovation and community reflection in this project. YLW received $500,000 from the Province’s Mass Timber Demonstration Program, which aims to grow B.C.’s mass timber and engineered wood products industry and position B.C. as a world leader in wood design, engineering and construction. An important design consideration for the ATB Expansion is to incorporate characteristics that showcase our local community. The use of mass timber plays a meaningful role in conveying our region’s natural beauty, heritage and character.

The Kelowna International Airport (YLW) is proud to share a significant project milestone for Airport Terminal Building (ATB) expansion – the mass timber roof structure of the facility is now complete. The use of mass timber throughout the terminal building expansion highlights the airport’s commitment to sustainability, innovation and community reflection in this project. YLW received $500,000 from the Province’s Mass Timber Demonstration Program, which aims to grow B.C.’s mass timber and engineered wood products industry and position B.C. as a world leader in wood design, engineering and construction. An important design consideration for the ATB Expansion is to incorporate characteristics that showcase our local community. The use of mass timber plays a meaningful role in conveying our region’s natural beauty, heritage and character.

TORONTO — A mass timber showcase on Toronto’s George Brown campus is also a study in collaboration and innovation. George Brown College’s Nerys Rau, Moriyama Teshima Architects partner Philip Silverstein and PCL’s Mike Love all explained the process behind building Limberlost Place at a session titled Exploring Limberlost Place: at the Canada Green Building Council’s Building Lasting Change conference held recently in downtown Vancouver. Limberlost Place is a 10-storey mass-timber net-zero building that achieved occupancy in January. …Silverstein said the building is rated at Tier 4 of the Toronto Green Standard, adding no other building in the city has reached that metric. “It’s like LEED Platinum on steroids,” Silverstein said. Love said the number one question was “what if the wood gets wet?” “It’s OK for wood to get wet. Just remove any ponding water and let it dry. It wants to breathe,” he said.

TORONTO — A mass timber showcase on Toronto’s George Brown campus is also a study in collaboration and innovation. George Brown College’s Nerys Rau, Moriyama Teshima Architects partner Philip Silverstein and PCL’s Mike Love all explained the process behind building Limberlost Place at a session titled Exploring Limberlost Place: at the Canada Green Building Council’s Building Lasting Change conference held recently in downtown Vancouver. Limberlost Place is a 10-storey mass-timber net-zero building that achieved occupancy in January. …Silverstein said the building is rated at Tier 4 of the Toronto Green Standard, adding no other building in the city has reached that metric. “It’s like LEED Platinum on steroids,” Silverstein said. Love said the number one question was “what if the wood gets wet?” “It’s OK for wood to get wet. Just remove any ponding water and let it dry. It wants to breathe,” he said.

A decade-spanning political battle between housing developers and defenders of California’s preeminent environmental law likely came to an end this afternoon with only a smattering of “no” votes. The forces of housing won. With the passage of a state budget-related housing bill, the California Environmental Quality Act will be a non-issue for a decisive swath of urban residential development in California. In practice, that means most new apartment buildings will no longer face the open threat of environmental litigation. It also means most urban developers will no longer have to study, predict and mitigate the ways that new housing might affect local traffic, air pollution, flora and fauna, noise levels, groundwater quality and objects of historic or archeological significance. And it means that when housing advocates argue that the state isn’t doing enough to build more homes amid crippling rents and stratospheric prices, they won’t — with a few exceptions — have CEQA to blame anymore.

A decade-spanning political battle between housing developers and defenders of California’s preeminent environmental law likely came to an end this afternoon with only a smattering of “no” votes. The forces of housing won. With the passage of a state budget-related housing bill, the California Environmental Quality Act will be a non-issue for a decisive swath of urban residential development in California. In practice, that means most new apartment buildings will no longer face the open threat of environmental litigation. It also means most urban developers will no longer have to study, predict and mitigate the ways that new housing might affect local traffic, air pollution, flora and fauna, noise levels, groundwater quality and objects of historic or archeological significance. And it means that when housing advocates argue that the state isn’t doing enough to build more homes amid crippling rents and stratospheric prices, they won’t — with a few exceptions — have CEQA to blame anymore.

I recently gave my electric pressure washer a vigorous workout. …Years ago, I walked into a lumber company to purchase materials and saw a placard on the counter advertising new maintenance-free pressure-treated lumber. Yes, at one time, residential pressure-treated lumber was a new thing. …We all discovered the claim was wrong. Pressure-treated lumber requires extensive maintenance. …This reality led to the first generation of composite decking. I remember when Trex was introduced. It dominated the marketplace, even though it was quite unattractive. It, too, was marketed as maintenance-free. Millions of other homeowners demanded a more realistic composite deck material. Generations two and three of composite decking followed. …The corporate attorneys for some decking manufacturers have reined in the optimistic marketing managers. You’ll now see clever descriptions such as “minimal maintenance.”

I recently gave my electric pressure washer a vigorous workout. …Years ago, I walked into a lumber company to purchase materials and saw a placard on the counter advertising new maintenance-free pressure-treated lumber. Yes, at one time, residential pressure-treated lumber was a new thing. …We all discovered the claim was wrong. Pressure-treated lumber requires extensive maintenance. …This reality led to the first generation of composite decking. I remember when Trex was introduced. It dominated the marketplace, even though it was quite unattractive. It, too, was marketed as maintenance-free. Millions of other homeowners demanded a more realistic composite deck material. Generations two and three of composite decking followed. …The corporate attorneys for some decking manufacturers have reined in the optimistic marketing managers. You’ll now see clever descriptions such as “minimal maintenance.” In an age of sleek finishes and synthetic shortcuts, timber framing offers something few modern materials can: substance. There’s a quiet grandeur to exposed beams that hold not only the weight of a home but the stories it gathers over time. The appeal isn’t rooted in nostalgia—it comes from discernment. Choosing timber is a commitment to craftsmanship, to the feel of hand-hewn structure beneath polished design. Bespoke estates, mountain retreats, and coastal getaways are embracing timber as both a form and a functional element. No longer reserved for rustic cabins or historical reproductions, it’s becoming the architectural signature of homes designed with permanence in mind. That kind of durability begins with sourcing, ensuring the materials behind the beauty are as intentional as the design itself. Timber framing is one of the oldest construction methods still in use, with roots stretching back over a thousand years.

In an age of sleek finishes and synthetic shortcuts, timber framing offers something few modern materials can: substance. There’s a quiet grandeur to exposed beams that hold not only the weight of a home but the stories it gathers over time. The appeal isn’t rooted in nostalgia—it comes from discernment. Choosing timber is a commitment to craftsmanship, to the feel of hand-hewn structure beneath polished design. Bespoke estates, mountain retreats, and coastal getaways are embracing timber as both a form and a functional element. No longer reserved for rustic cabins or historical reproductions, it’s becoming the architectural signature of homes designed with permanence in mind. That kind of durability begins with sourcing, ensuring the materials behind the beauty are as intentional as the design itself. Timber framing is one of the oldest construction methods still in use, with roots stretching back over a thousand years.  PORTLAND, Oregon – The Port of Portland is leasing a former marine terminal to a mass timber company as part of an effort to spur housing development and job growth in the area. On Wednesday, the Port of Portland approved a lease for Zaugg Timber Solutions to open a factory at the Port’s Mass Timber and Housing Innovation Campus at Terminal 2. …“Our partnership with ZTS marks a major leap forward in developing the Mass Timber and Housing Innovation Campus at T2,” said Kimberly Branam. “Their new manufacturing facility will boost our region’s economy by promoting sustainable forestry practices, creating quality jobs, and increasing housing production.” While the new 100,000-square-foot manufacturing facility is expected to open in 2028, ZTS will produce mass timber modular housing units, industrial and commercial buildings and other building components starting in 2026 in an interim manufacturing facility at the terminal, officials noted.

PORTLAND, Oregon – The Port of Portland is leasing a former marine terminal to a mass timber company as part of an effort to spur housing development and job growth in the area. On Wednesday, the Port of Portland approved a lease for Zaugg Timber Solutions to open a factory at the Port’s Mass Timber and Housing Innovation Campus at Terminal 2. …“Our partnership with ZTS marks a major leap forward in developing the Mass Timber and Housing Innovation Campus at T2,” said Kimberly Branam. “Their new manufacturing facility will boost our region’s economy by promoting sustainable forestry practices, creating quality jobs, and increasing housing production.” While the new 100,000-square-foot manufacturing facility is expected to open in 2028, ZTS will produce mass timber modular housing units, industrial and commercial buildings and other building components starting in 2026 in an interim manufacturing facility at the terminal, officials noted. Researchers in the Department of Forest Biomaterials are developing a proprietary material that could serve as a sustainable alternative to one of the world’s most significant sources of pollution: plastic foam. “Our material eliminates polystyrene foam materials that are filling landfills and persisting as litter in the environment,” said Richard Venditti, the Elis-Signe Olsson Professor of Pulp and Paper Science and Engineering. Plastic foam, often known by the brand name Styrofoam, is used in many everyday products — from disposable food and beverage containers like cups and plates to shipping materials such as packing peanuts and protective packaging. While convenient, plastic foam presents a significant environmental challenge due to its lack of biodegradability and difficulty in recycling. Estimates indicate that plastic foam takes up to 30% of landfill space globally.

Researchers in the Department of Forest Biomaterials are developing a proprietary material that could serve as a sustainable alternative to one of the world’s most significant sources of pollution: plastic foam. “Our material eliminates polystyrene foam materials that are filling landfills and persisting as litter in the environment,” said Richard Venditti, the Elis-Signe Olsson Professor of Pulp and Paper Science and Engineering. Plastic foam, often known by the brand name Styrofoam, is used in many everyday products — from disposable food and beverage containers like cups and plates to shipping materials such as packing peanuts and protective packaging. While convenient, plastic foam presents a significant environmental challenge due to its lack of biodegradability and difficulty in recycling. Estimates indicate that plastic foam takes up to 30% of landfill space globally.

The fashion industry is often seen as a voracious, thirsty villain that extracts billions of liters of water out of the environment. …These conditions are the biggest ‘WHY’ for Spinnova, a Finnish startup that works tirelessly to create technology for sustainable natural fibers to match its growing demand. …But before we delve into the details, would you believe the core idea for Spinnova was actually born from… a spiderweb? Back in 2009, Juha Salmela, a cellulose expert from Finland attended an Oxford University conference. He heard a presentation from a leading spider researcher, who explained the similarities between spiderweb’s protein and nanocellulose. And, that happened to be his Eureka moment. What if wood fiber could be spun into textile fiber in a similar manner? Fast forward to 2023, the wood-based Spinnova fiber was born. …The process at Spinnova starts with sourcing cellulose-rich raw materials such as FSC-certified wood pulp.

The fashion industry is often seen as a voracious, thirsty villain that extracts billions of liters of water out of the environment. …These conditions are the biggest ‘WHY’ for Spinnova, a Finnish startup that works tirelessly to create technology for sustainable natural fibers to match its growing demand. …But before we delve into the details, would you believe the core idea for Spinnova was actually born from… a spiderweb? Back in 2009, Juha Salmela, a cellulose expert from Finland attended an Oxford University conference. He heard a presentation from a leading spider researcher, who explained the similarities between spiderweb’s protein and nanocellulose. And, that happened to be his Eureka moment. What if wood fiber could be spun into textile fiber in a similar manner? Fast forward to 2023, the wood-based Spinnova fiber was born. …The process at Spinnova starts with sourcing cellulose-rich raw materials such as FSC-certified wood pulp. UK waste wood market processed over 96% of material, annual statistics published this month by the Wood Recyclers’ Association (WRA) showed. The association said that there was “strong demand” for material in 2024. According to the statistics, 4.5 million tonnes of waste wood arose in the UK last year. Of this, 4.33 million tonnes (96%) were sent for reuse, recycling or recovery, the figures showed. The organisation compiled the 2024 figures through its annual survey of members who handle approximately 90% of the market, combining the findings with latest industry data. The figures are somewhat similar to 2023 which saw 97% of the material processed.

UK waste wood market processed over 96% of material, annual statistics published this month by the Wood Recyclers’ Association (WRA) showed. The association said that there was “strong demand” for material in 2024. According to the statistics, 4.5 million tonnes of waste wood arose in the UK last year. Of this, 4.33 million tonnes (96%) were sent for reuse, recycling or recovery, the figures showed. The organisation compiled the 2024 figures through its annual survey of members who handle approximately 90% of the market, combining the findings with latest industry data. The figures are somewhat similar to 2023 which saw 97% of the material processed. As per a study documented in RSC Sustainability (Royal Society Of Chemistry), researchers have explored a new approach to using cellulose fibre manufacturing. The study highlighted the use of waste products from agriculture, which Sweden has in abundance. Taking a leap from commonly researched wood-based cellulose, the researchers instead focussed on products including oat husks, potato pulp, wheat straw, and sugar beet pulp to create dissolving pulp for clothes – a key ingredient in making textiles. In this regard, Diana Bernin, Assistant Professor at the Department of Chemistry and Chemical Engineering at Chalmers University of Technology and senior researcher in the study, mentioned this study, which is centered on generating textile from waste products, as a significant step in creating a circular economy. She also added that these waste products are more beneficial than using cotton.

As per a study documented in RSC Sustainability (Royal Society Of Chemistry), researchers have explored a new approach to using cellulose fibre manufacturing. The study highlighted the use of waste products from agriculture, which Sweden has in abundance. Taking a leap from commonly researched wood-based cellulose, the researchers instead focussed on products including oat husks, potato pulp, wheat straw, and sugar beet pulp to create dissolving pulp for clothes – a key ingredient in making textiles. In this regard, Diana Bernin, Assistant Professor at the Department of Chemistry and Chemical Engineering at Chalmers University of Technology and senior researcher in the study, mentioned this study, which is centered on generating textile from waste products, as a significant step in creating a circular economy. She also added that these waste products are more beneficial than using cotton. The ultimate problem for architects is that the most sustainable building is always the one that is already there. There is a huge amount written about green buildings, much of it nonsense. There is some confusion about buildings layered in vines and living walls, and buildings that actually are green. Contemporary architecture’s issue is mostly embodied in one material: concrete. …The rate at which we are still using it is astonishing: half of all the stuff manufactured by weight is concrete. From 2011 to 2013, China used more concrete than the US had in the whole of the 20th century. …There are signs, however, that architects are beginning to shake things up. The first credible alternative is, perhaps a little ironically, that oldest of building materials, timber. [A Financial Times subscription may be required to read the full story]

The ultimate problem for architects is that the most sustainable building is always the one that is already there. There is a huge amount written about green buildings, much of it nonsense. There is some confusion about buildings layered in vines and living walls, and buildings that actually are green. Contemporary architecture’s issue is mostly embodied in one material: concrete. …The rate at which we are still using it is astonishing: half of all the stuff manufactured by weight is concrete. From 2011 to 2013, China used more concrete than the US had in the whole of the 20th century. …There are signs, however, that architects are beginning to shake things up. The first credible alternative is, perhaps a little ironically, that oldest of building materials, timber. [A Financial Times subscription may be required to read the full story] Although a casual observer just sees the bark on a tree, a lumber expert might envision the potential for boards inside, thinking of the bark largely as waste. In many cases, bark does turn into waste in the logging industry. That’s lots of waste, because bark can account for up to 15% of a tree’s weight, and “only a fraction of this is currently being utilized, primarily for landscaping or for energy; the rest is left at the harvest or handling site to naturally decompose,” according to Sumanth Ranganathan, Dr.-Ing, a biochemical engineer at Scion, a research institute in Rotorua, New Zealand, and his colleagues. For some trees, though, that wasted bark is a potential treasure-trove of biopharmaceuticals, from anti-inflammatories to cancer-fighting drugs. …Each year, the country’s logging industry produces about 2.5 million metric tons of bark. Ranganathan’s team envisions feeding that into a bark-based biorefinery.

Although a casual observer just sees the bark on a tree, a lumber expert might envision the potential for boards inside, thinking of the bark largely as waste. In many cases, bark does turn into waste in the logging industry. That’s lots of waste, because bark can account for up to 15% of a tree’s weight, and “only a fraction of this is currently being utilized, primarily for landscaping or for energy; the rest is left at the harvest or handling site to naturally decompose,” according to Sumanth Ranganathan, Dr.-Ing, a biochemical engineer at Scion, a research institute in Rotorua, New Zealand, and his colleagues. For some trees, though, that wasted bark is a potential treasure-trove of biopharmaceuticals, from anti-inflammatories to cancer-fighting drugs. …Each year, the country’s logging industry produces about 2.5 million metric tons of bark. Ranganathan’s team envisions feeding that into a bark-based biorefinery. IRELAND — The Government is branching out in its bid to solve the housing crisis with a new “Wood First” plan that will see timber become the main building material used to build our homes, schools and libraries. It comes as the Cabinet will today give the green light to emergency legislation to extend rent pressure zones across the country in a scramble to stop greedy landlords cashing in on the Coalition’s rental policy changes. Forestry Minister Micheal Healy-Rae said Ireland has excellent forest resources that are being underused in our construction sector

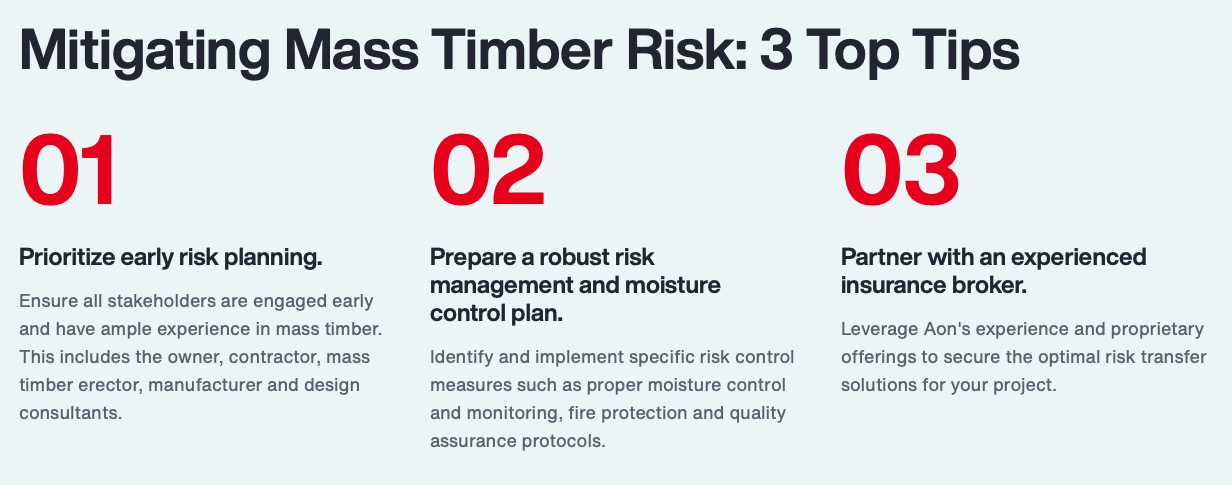

IRELAND — The Government is branching out in its bid to solve the housing crisis with a new “Wood First” plan that will see timber become the main building material used to build our homes, schools and libraries. It comes as the Cabinet will today give the green light to emergency legislation to extend rent pressure zones across the country in a scramble to stop greedy landlords cashing in on the Coalition’s rental policy changes. Forestry Minister Micheal Healy-Rae said Ireland has excellent forest resources that are being underused in our construction sector Mass timber construction is gaining traction for its sustainability and efficiency, yet it brings distinct insurance and risk management challenges that require industry collaboration and proactive strategies. Key Takeaways from this Article:

Mass timber construction is gaining traction for its sustainability and efficiency, yet it brings distinct insurance and risk management challenges that require industry collaboration and proactive strategies. Key Takeaways from this Article: Maximising the use of bio-based products is key to meeting current sustainability targets. Yet according to sustainability consultancy Metabolic, using bio-based products for half of new housing in Europe would require production of engineered timber to increase nearly fivefold, and roundwood by four and a half times. Given the improbability of an uplift in production on that scale, as well as the current rapid growth in global demand and the UK’s own limited timber harvest, using the country’s waste timber to make ‘cross-laminated secondary timber’ – CLST – would seem to make a great deal of sense. Rather than its current fates of combustion for energy recovery, chipping for MDF, dumping in landfill, and other low-grade, non-circular activities, incorporating this plentiful material into supply chains would benefit the construction industry, as well as the country’s economy and environment. And it would also seem to be a highly achievable ambition – so why isn’t it happening?

Maximising the use of bio-based products is key to meeting current sustainability targets. Yet according to sustainability consultancy Metabolic, using bio-based products for half of new housing in Europe would require production of engineered timber to increase nearly fivefold, and roundwood by four and a half times. Given the improbability of an uplift in production on that scale, as well as the current rapid growth in global demand and the UK’s own limited timber harvest, using the country’s waste timber to make ‘cross-laminated secondary timber’ – CLST – would seem to make a great deal of sense. Rather than its current fates of combustion for energy recovery, chipping for MDF, dumping in landfill, and other low-grade, non-circular activities, incorporating this plentiful material into supply chains would benefit the construction industry, as well as the country’s economy and environment. And it would also seem to be a highly achievable ambition – so why isn’t it happening?