The broader adoption of wood construction in Guangdong can be traced back to a foundational moment in 2007, marked by the completion of a BC-supported wood structure in Zhujiang Park, Guangzhou. Developed through cooperation between Guangdong Province and British Columbia, and implemented by Canada Wood and the Guangzhou Municipal Bureau of City Engineering and Gardening, the project was explicitly conceived as a technical demonstration. Canadian-sourced wood products were treated with advanced anti-corrosion technologies to address long-standing concerns about durability under South China’s hot and humid conditions. …What distinguishes this project is not its architectural scale, but its temporal performance. Nearly two decades on, the structure …remains in continuous public use and has become one of Zhujiang Park’s most popular destinations… Guangming Equestrian Centre demonstrates that Douglas fir–based mass timber systems can reliably support mega-span applications under demanding load and performance requirements, extending the practical range of wood construction in China…

The broader adoption of wood construction in Guangdong can be traced back to a foundational moment in 2007, marked by the completion of a BC-supported wood structure in Zhujiang Park, Guangzhou. Developed through cooperation between Guangdong Province and British Columbia, and implemented by Canada Wood and the Guangzhou Municipal Bureau of City Engineering and Gardening, the project was explicitly conceived as a technical demonstration. Canadian-sourced wood products were treated with advanced anti-corrosion technologies to address long-standing concerns about durability under South China’s hot and humid conditions. …What distinguishes this project is not its architectural scale, but its temporal performance. Nearly two decades on, the structure …remains in continuous public use and has become one of Zhujiang Park’s most popular destinations… Guangming Equestrian Centre demonstrates that Douglas fir–based mass timber systems can reliably support mega-span applications under demanding load and performance requirements, extending the practical range of wood construction in China…

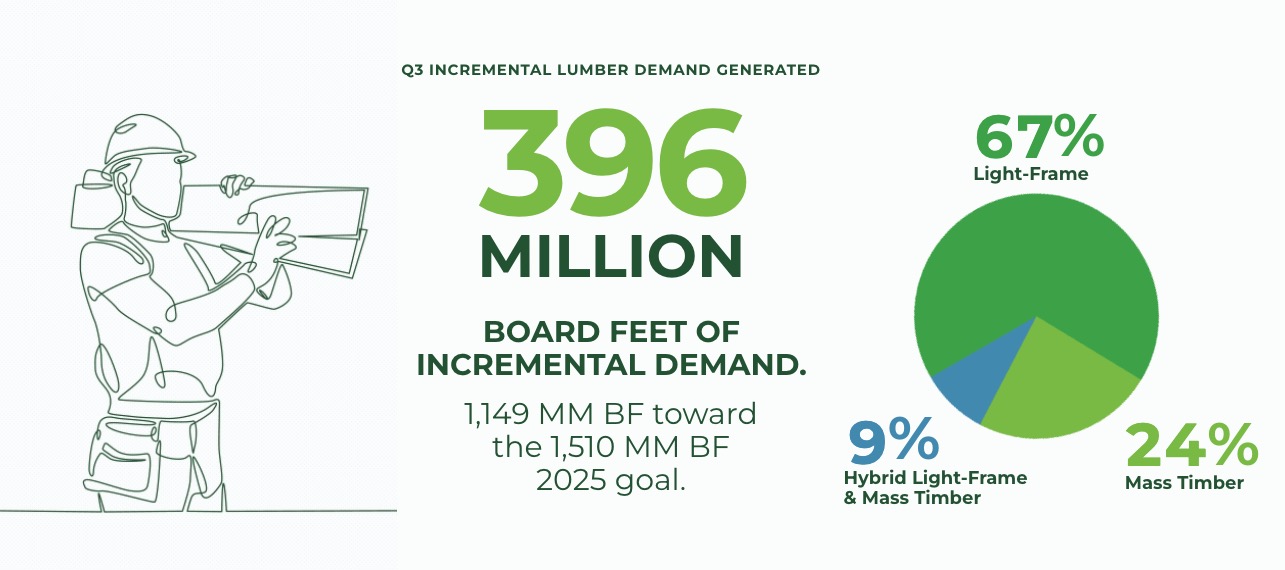

The Softwood Lumber Board has released its Q3 2025 Report, highlighting significant progress tied to its new strategic plan. This quarter, SLB-funded programs advanced a coordinated strategy centered on high-opportunity sectors—1-8 story multifamily, commercial, K-12 education, and the fast-growing industrial segment—while accelerating project conversions, strengthening building code support, scaling post-secondary education, and expanding outreach in key cities.

The Softwood Lumber Board has released its Q3 2025 Report, highlighting significant progress tied to its new strategic plan. This quarter, SLB-funded programs advanced a coordinated strategy centered on high-opportunity sectors—1-8 story multifamily, commercial, K-12 education, and the fast-growing industrial segment—while accelerating project conversions, strengthening building code support, scaling post-secondary education, and expanding outreach in key cities.

The Canadian Wood Council (CWC) welcomes the announcement made today by the Honourable Tim Hodgson, Minister of Energy and Natural Resources. The event celebrated funding for projects that strengthen Canada’s forestry sector and foster innovation in wood-based solutions. CWC received $8.5 million since 2023 to expand the use of wood-based products, broaden education on wood construction and contribute to the advancement of the National Building Code. …This funding has allowed CWC and its WoodWorks program to support design and construction professionals with expert resources, tools, and guidance that help accelerate the adoption of wood construction nationwide. As we continue this work, we will help catalyze sustainable demand for construction solutions that are not only innovative but also replicable and rapidly deployed, approaches that will help address Canada’s housing and affordability challenges at scale.

The Canadian Wood Council (CWC) welcomes the announcement made today by the Honourable Tim Hodgson, Minister of Energy and Natural Resources. The event celebrated funding for projects that strengthen Canada’s forestry sector and foster innovation in wood-based solutions. CWC received $8.5 million since 2023 to expand the use of wood-based products, broaden education on wood construction and contribute to the advancement of the National Building Code. …This funding has allowed CWC and its WoodWorks program to support design and construction professionals with expert resources, tools, and guidance that help accelerate the adoption of wood construction nationwide. As we continue this work, we will help catalyze sustainable demand for construction solutions that are not only innovative but also replicable and rapidly deployed, approaches that will help address Canada’s housing and affordability challenges at scale.

International Pulp Week (IPW) is the premier annual gathering of the global market pulp industry, hosted by the Pulp and Paper Products Council. As the leading event dedicated exclusively to the market pulp sector, IPW provides a unique platform for producers, end-users, and key stakeholders to exchange insights, strengthen relationships, and explore the trends shaping the industry’s future.

International Pulp Week (IPW) is the premier annual gathering of the global market pulp industry, hosted by the Pulp and Paper Products Council. As the leading event dedicated exclusively to the market pulp sector, IPW provides a unique platform for producers, end-users, and key stakeholders to exchange insights, strengthen relationships, and explore the trends shaping the industry’s future.

EDMONTON, AB – Celebrated for its pioneering mass timber design and construction, commitment to safety and collaborative excellence, Limberlost Place has been named the Global Best Project of the Year by Engineering News-Record (ENR). In addition to PCL Construction and partners taking home the top honour, PCL was also awarded ENR’s Global Best Projects Award for Limberlost Place in the Education/Research category. …Ontario’s first institutional building of its kind, George Brown Polytechnic’s Limberlost Place has set a new precedent for mass timber construction as a model for sustainable, green building innovation. Located in Toronto, Ontario, the 10-story mass timber, net-zero educational facility integrates first-of-its-kind solutions including: Groundbreaking slab band structural system that advances the use of mass timber in multi-storey buildings; North America’s largest mass timber columns soaring three stories tall; and a striking mass timber feature stair, spanning levels three to five as a centerpiece of architectural design.

EDMONTON, AB – Celebrated for its pioneering mass timber design and construction, commitment to safety and collaborative excellence, Limberlost Place has been named the Global Best Project of the Year by Engineering News-Record (ENR). In addition to PCL Construction and partners taking home the top honour, PCL was also awarded ENR’s Global Best Projects Award for Limberlost Place in the Education/Research category. …Ontario’s first institutional building of its kind, George Brown Polytechnic’s Limberlost Place has set a new precedent for mass timber construction as a model for sustainable, green building innovation. Located in Toronto, Ontario, the 10-story mass timber, net-zero educational facility integrates first-of-its-kind solutions including: Groundbreaking slab band structural system that advances the use of mass timber in multi-storey buildings; North America’s largest mass timber columns soaring three stories tall; and a striking mass timber feature stair, spanning levels three to five as a centerpiece of architectural design.

Toilet paper…is typically made with trees, energy-intensive manufacturing processes and chemicals that can pollute the environment. Experts say more consumers are seeking toilet paper made from recycled content or sustainable materials, but it can be hard to know what to look for. Sustainable toilet paper often costs more, but can have significant environmental benefits. According to the Environmental Paper Network, a coalition of nonprofits, more than 1 billion gallons of water and 1.6 million trees could be saved if every American used one roll of toilet paper made from recycled content instead of a roll made from forest fibres. Increasingly, manufacturers are making toilet paper from recycled paper products … using chlorine-free bleaching techniques. …Looking for recycled content is a good place for environmentally conscious consumers to start, said Gary Bull, at the University of British Columbia. Preconsumer materials include scrap materials from manufacturing or unsold paper. Postconsumer materials come from used paper products.

Toilet paper…is typically made with trees, energy-intensive manufacturing processes and chemicals that can pollute the environment. Experts say more consumers are seeking toilet paper made from recycled content or sustainable materials, but it can be hard to know what to look for. Sustainable toilet paper often costs more, but can have significant environmental benefits. According to the Environmental Paper Network, a coalition of nonprofits, more than 1 billion gallons of water and 1.6 million trees could be saved if every American used one roll of toilet paper made from recycled content instead of a roll made from forest fibres. Increasingly, manufacturers are making toilet paper from recycled paper products … using chlorine-free bleaching techniques. …Looking for recycled content is a good place for environmentally conscious consumers to start, said Gary Bull, at the University of British Columbia. Preconsumer materials include scrap materials from manufacturing or unsold paper. Postconsumer materials come from used paper products.

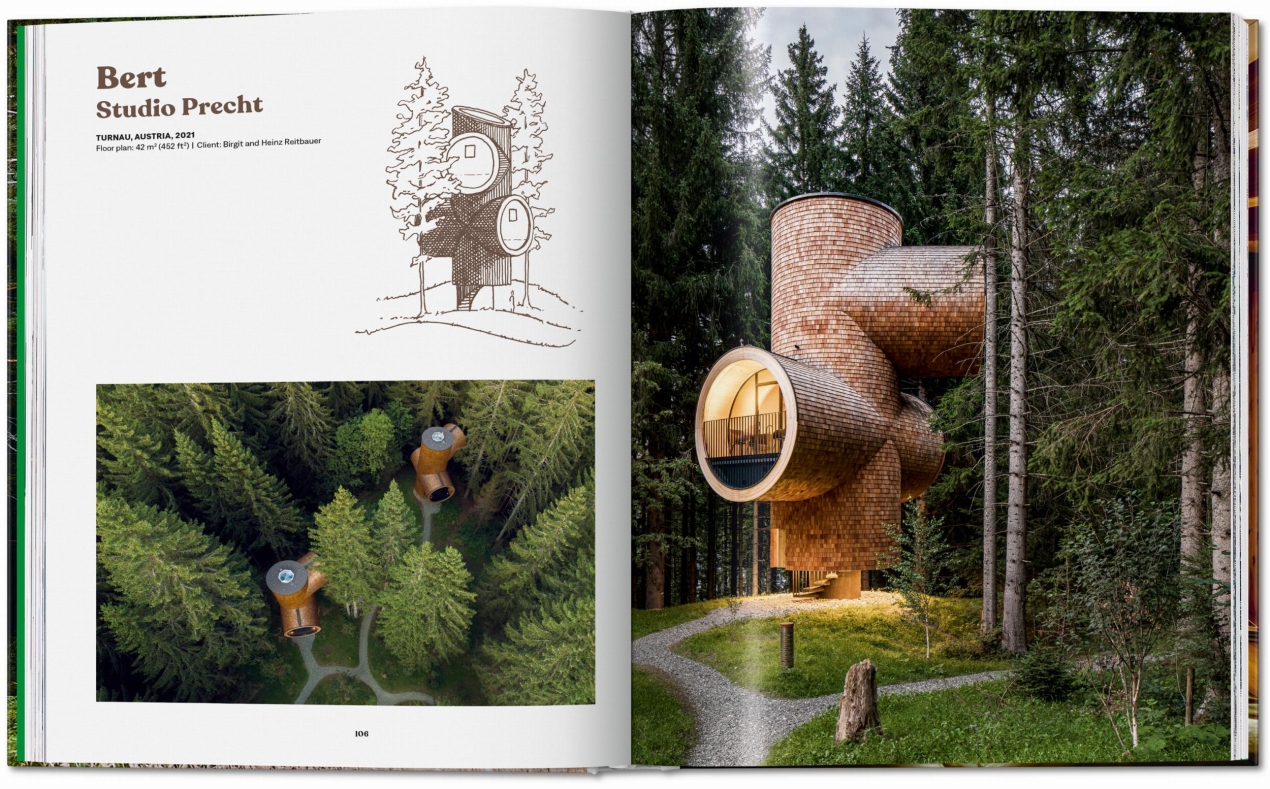

…Biophilia — a concept that’s been introduced in the pages of Health & Home before — is a term coined by the sociologist Erich Fromm and later adopted by biologist Edward O. Wilson in a 1984 book of the same name. Bill Browning, co-founder of the New York City-based sustainability consulting firm Terrapin Bright Green and chair of the Biophilic Institute, defines it as the “innate affiliation of humans to other living organisms and lifelike processes.” …Browning’s firm published a paper in 2022 titled “The Nature of Wood,” which distilled the available research on why people tend to gravitate to wood as a natural material. …Browning’s company has summarized some of biophilia’s high-level takeaways in a paper called “14 Patterns of Biophilic Design: Improving Health & Well-Being in the Built Environment.” In it, they outline how light, water, airflow and even a very primal sense of safety can positively affect cognitive performance as well as our mind-body relationship.

…Biophilia — a concept that’s been introduced in the pages of Health & Home before — is a term coined by the sociologist Erich Fromm and later adopted by biologist Edward O. Wilson in a 1984 book of the same name. Bill Browning, co-founder of the New York City-based sustainability consulting firm Terrapin Bright Green and chair of the Biophilic Institute, defines it as the “innate affiliation of humans to other living organisms and lifelike processes.” …Browning’s firm published a paper in 2022 titled “The Nature of Wood,” which distilled the available research on why people tend to gravitate to wood as a natural material. …Browning’s company has summarized some of biophilia’s high-level takeaways in a paper called “14 Patterns of Biophilic Design: Improving Health & Well-Being in the Built Environment.” In it, they outline how light, water, airflow and even a very primal sense of safety can positively affect cognitive performance as well as our mind-body relationship.

Mark Latino is the CEO of Lee Display, a Fairfield, California-based company… that still makes artificial Christmas trees, producing around 10,000 each year. Tariffs shone a twinkling light this year on fake Christmas trees — and the extent to which America depends on other countries for its plastic fir trees. Prices for fake trees rose 10% to 15% this year due to the new import taxes, according to the American Christmas Tree Association, a trade group. Tree sellers cut their orders and paid higher tariffs for the stock they brought in. Despite those issues, tree companies say they aren’t likely to shift large-scale production back to the US after decades in Asia. Fake trees are labor-intensive and require holiday lights and other components the US doesn’t make. …About 80% of the US residents who put up a Christmas tree this year planned to use a fake one. …That percentage has been unchanged for at least 15 years.

Mark Latino is the CEO of Lee Display, a Fairfield, California-based company… that still makes artificial Christmas trees, producing around 10,000 each year. Tariffs shone a twinkling light this year on fake Christmas trees — and the extent to which America depends on other countries for its plastic fir trees. Prices for fake trees rose 10% to 15% this year due to the new import taxes, according to the American Christmas Tree Association, a trade group. Tree sellers cut their orders and paid higher tariffs for the stock they brought in. Despite those issues, tree companies say they aren’t likely to shift large-scale production back to the US after decades in Asia. Fake trees are labor-intensive and require holiday lights and other components the US doesn’t make. …About 80% of the US residents who put up a Christmas tree this year planned to use a fake one. …That percentage has been unchanged for at least 15 years. One year after wildfires tore through neighborhoods in Los Angeles County, killing at least 31 people and destroying more than 10,000 buildings, architects and developers are rethinking what home looks like in LA, and how resilient residential architecture evolves. …So far, hundreds of new homes have been submitted for permitting, but it’s a process shaping out to be an uneven one, based on damage, insurance and wealth. Affected homeowners are grappling with the details of fire-resilient construction and landscaping techniques, along with some more fundamental questions about what their communities should look like. …These 10 projects — all in various stages of completion — showcase several of the design concepts, construction techniques and development proposals in play as LA’s post-fire rebuilding process begins. …Many forthcoming home projects emphasize the latest in wildfire-resilience features: Think noncombustible sheathing and roof materials, triple-glazed windows that can resist high heat, and defensible outdoor space.

One year after wildfires tore through neighborhoods in Los Angeles County, killing at least 31 people and destroying more than 10,000 buildings, architects and developers are rethinking what home looks like in LA, and how resilient residential architecture evolves. …So far, hundreds of new homes have been submitted for permitting, but it’s a process shaping out to be an uneven one, based on damage, insurance and wealth. Affected homeowners are grappling with the details of fire-resilient construction and landscaping techniques, along with some more fundamental questions about what their communities should look like. …These 10 projects — all in various stages of completion — showcase several of the design concepts, construction techniques and development proposals in play as LA’s post-fire rebuilding process begins. …Many forthcoming home projects emphasize the latest in wildfire-resilience features: Think noncombustible sheathing and roof materials, triple-glazed windows that can resist high heat, and defensible outdoor space.

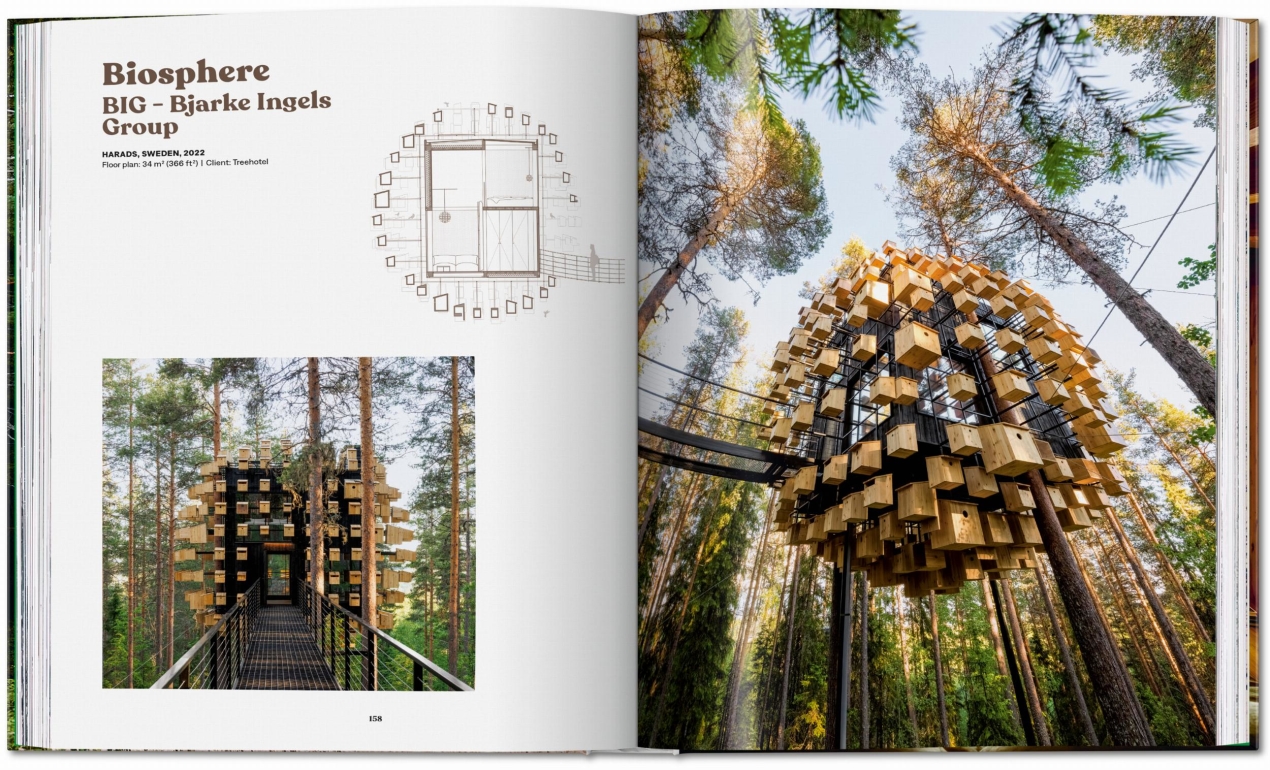

Schools built with mass timber have recently opened to positive community response in the Seattle, Renton and Highline school districts, and another is under construction in West Seattle. … Throughout the United States and Canada, about 150 educational projects have already been built with mass timber. Mass timber products such as Glulam and Cross-Laminated Timber are made from lumber stacked in layers to create large components — columns, beams and panels that become the structures of buildings of all types. These large building components drive efficiency in construction while reducing the carbon footprint. In Washington, mass timber can now be used in buildings up to 18 stories, a renewable, resilient alternative to steel and concrete. The Pacific Northwest is well-positioned to be a leader in this industry. …structures made from mass timber, where the wood remains exposed, have

Schools built with mass timber have recently opened to positive community response in the Seattle, Renton and Highline school districts, and another is under construction in West Seattle. … Throughout the United States and Canada, about 150 educational projects have already been built with mass timber. Mass timber products such as Glulam and Cross-Laminated Timber are made from lumber stacked in layers to create large components — columns, beams and panels that become the structures of buildings of all types. These large building components drive efficiency in construction while reducing the carbon footprint. In Washington, mass timber can now be used in buildings up to 18 stories, a renewable, resilient alternative to steel and concrete. The Pacific Northwest is well-positioned to be a leader in this industry. …structures made from mass timber, where the wood remains exposed, have

Bamboo tissue’s green image fades once you factor in coal-powered manufacturing. Bamboo tissue paper produced in China has become a popular option for shoppers looking to reduce their environmental impact. Despite its green reputation, new research suggests these products may not deliver the climate advantages many consumers expect. In some cases, bamboo tissue may even have a greater environmental footprint than tissue made in the United States. A recent

Bamboo tissue’s green image fades once you factor in coal-powered manufacturing. Bamboo tissue paper produced in China has become a popular option for shoppers looking to reduce their environmental impact. Despite its green reputation, new research suggests these products may not deliver the climate advantages many consumers expect. In some cases, bamboo tissue may even have a greater environmental footprint than tissue made in the United States. A recent

Japan-based materials experts have made impressive progress in the search for a better biodegradable plastic. The breakthrough starts with an abundant material: cellulose from wood pulp. Takuzo Aida, RIKEN Center for Emergent Matter Science research lead, said in a news release that “about one trillion tons” are naturally produced annually. Using it successfully as part of a new plastic could have a widespread impact, because most types of the material take decades to hundreds of years to break down. “This technology will help protect the Earth from plastic pollution,” Aida said in the RIKEN report. …Unlike other biodegradable plastics, RIKEN’s innovation also eliminates harmful microplastics, tiny particles that have saturated our world — found in soil, oceans, and even our bodies.

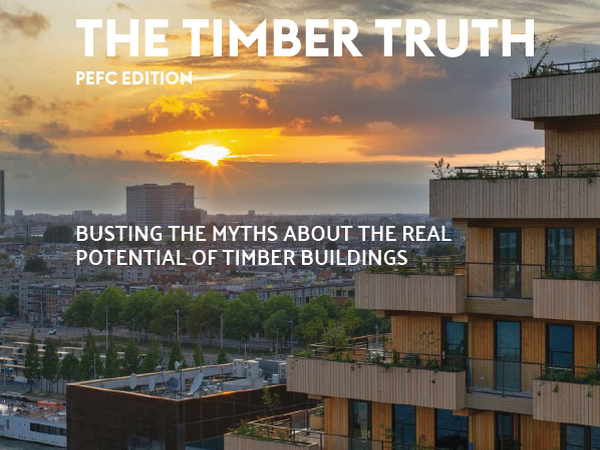

Japan-based materials experts have made impressive progress in the search for a better biodegradable plastic. The breakthrough starts with an abundant material: cellulose from wood pulp. Takuzo Aida, RIKEN Center for Emergent Matter Science research lead, said in a news release that “about one trillion tons” are naturally produced annually. Using it successfully as part of a new plastic could have a widespread impact, because most types of the material take decades to hundreds of years to break down. “This technology will help protect the Earth from plastic pollution,” Aida said in the RIKEN report. …Unlike other biodegradable plastics, RIKEN’s innovation also eliminates harmful microplastics, tiny particles that have saturated our world — found in soil, oceans, and even our bodies. Recent studies suggest that paper-based advertising may hold a more sustainable footprint than its digital counterpart. This revelation challenges the widely held assumption that ‘going paperless’ automatically equates to environmental responsibility. New data indicates that the full lifecycle impact of digital advertising – encompassing data centers, device manufacturing, and network infrastructure – generates a significantly larger carbon footprint than traditional print methods. The findings, originating from research conducted by the Öko-Institut in Germany and corroborated by analyses from The Telegraph, Emerce, and RetailTrends, highlight the often-overlooked environmental costs associated with the digital world. While paper production undeniably carries its own environmental burdens, advancements in sustainable forestry practices and paper recycling are mitigating these impacts. …Their findings consistently showed that paper-based advertising, particularly when utilizing recycled paper and responsible forestry practices, generated fewer greenhouse gas emissions than comparable digital campaigns.

Recent studies suggest that paper-based advertising may hold a more sustainable footprint than its digital counterpart. This revelation challenges the widely held assumption that ‘going paperless’ automatically equates to environmental responsibility. New data indicates that the full lifecycle impact of digital advertising – encompassing data centers, device manufacturing, and network infrastructure – generates a significantly larger carbon footprint than traditional print methods. The findings, originating from research conducted by the Öko-Institut in Germany and corroborated by analyses from The Telegraph, Emerce, and RetailTrends, highlight the often-overlooked environmental costs associated with the digital world. While paper production undeniably carries its own environmental burdens, advancements in sustainable forestry practices and paper recycling are mitigating these impacts. …Their findings consistently showed that paper-based advertising, particularly when utilizing recycled paper and responsible forestry practices, generated fewer greenhouse gas emissions than comparable digital campaigns.