©LinkedIn Eric Laignel

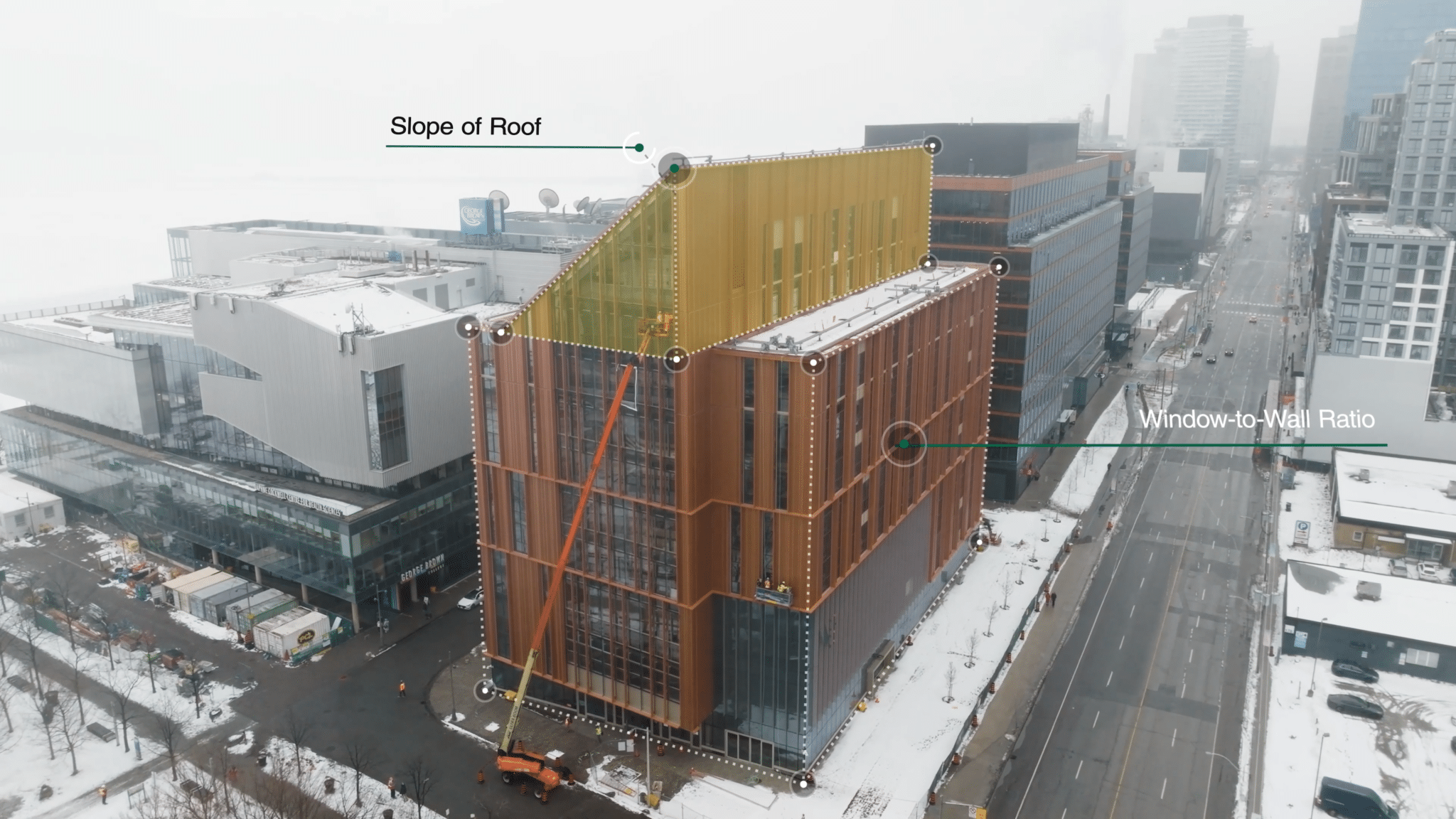

T3 RiNo, a groundbreaking six-story mass timber, Class-A, mixed-use office building in the heart of Denver’s vibrant RiNo (River North) neighborhood, has reached substantial completion. T3 RiNo was developed in collaboration with Hines, McCaffery, and La Caisse (formerly CDPQ), and sets a new standard for sustainable, innovative, and community-centric design. The “T3” stands for Timber, Transit, and Technology, elements woven into the building via thoughtful timber design, proximity to multiple transit options, and building systems focused on the needs of today’s tenants. All timber utilized was sourced from supplier Nordic Structures and manufactured by Chantiers Chibougamau in Québec, Canada. Pickard Chilton, an award-winning architecture studio best known for its innovative and cutting-edge design of corporate headquarters and campuses, served as the building’s design architect; the project team also included DLR Group, Whiting-Turner, Magnusson Klemencic Associates, Alvine Engineering, and S.A Miro.

The Canadian Wood Council (CWC) welcomes

The Canadian Wood Council (CWC) welcomes Forest Products Association of Canada (FPAC) welcomes

Forest Products Association of Canada (FPAC) welcomes Prime Minister Mark Carney announced Sunday afternoon the launch of Build Canada Homes, the federal government’s new agency that will oversee federal housing programs. The agency was part of the Liberals’ election promise to double housing construction. The government is touting Build Canada Homes as a centralized agency to oversee new affordable housing programs initiated at the federal level. Carney said the agency will “supercharge housing construction across Canada” by helping to build supportive and transitional housing in collaboration with provinces, territories and Indigenous communities. It will also expand “deeply affordable and community housing” and partner with private developers to build homes for the middle class. The prime minister also announced that former Toronto city councillor Ana Bailão will be the CEO of Build Canada Homes. …Carney said $13 billion is earmarked for the new agency.

Prime Minister Mark Carney announced Sunday afternoon the launch of Build Canada Homes, the federal government’s new agency that will oversee federal housing programs. The agency was part of the Liberals’ election promise to double housing construction. The government is touting Build Canada Homes as a centralized agency to oversee new affordable housing programs initiated at the federal level. Carney said the agency will “supercharge housing construction across Canada” by helping to build supportive and transitional housing in collaboration with provinces, territories and Indigenous communities. It will also expand “deeply affordable and community housing” and partner with private developers to build homes for the middle class. The prime minister also announced that former Toronto city councillor Ana Bailão will be the CEO of Build Canada Homes. …Carney said $13 billion is earmarked for the new agency.

Four new buildings in B.C. are each receiving $500,000 — totalling $2 million — to demonstrate and showcase the benefits of mass-timber construction. “Mass timber represents a transformative, locally sourced solution that’s generating significant employment opportunities, spurring cutting-edge innovation, and revitalizing rural economies across British Columbia,” said Ravi Kahlon, Minister of Jobs and Economic Growth. …The four projects were announced at the 2025 International Woodrise Congress. …Delivered through the Province’s Crown corporation Forestry Innovation Investment. The four projects are:

Four new buildings in B.C. are each receiving $500,000 — totalling $2 million — to demonstrate and showcase the benefits of mass-timber construction. “Mass timber represents a transformative, locally sourced solution that’s generating significant employment opportunities, spurring cutting-edge innovation, and revitalizing rural economies across British Columbia,” said Ravi Kahlon, Minister of Jobs and Economic Growth. …The four projects were announced at the 2025 International Woodrise Congress. …Delivered through the Province’s Crown corporation Forestry Innovation Investment. The four projects are:

A proposed 18-storey residential tower on St. Paul Street in downtown Kelowna will be constructed using mass timber, according to applications recently submitted to city planners. The city announced earlier this year that it was partnering with non-profit developer Housing Okanagan Foundation on the project for middle-income earners. Now a development permit and variance applications have been submitted for the property at 1428 St. Paul St. “If completed today, it would be the tallest mass timber residential building in Canada,” according to the application from project architect Lang Wilson Practice in Architecture Culture. “The use of mass timber also offers significant reductions in embodied carbon emissions. “This design aligns with the provincial and federal housing objectives while also incubating a building construction methodology that creates local manufacturing jobs.” Above the three-storey podium will be 15 residential floors and a rooftop terrace for all tenants.

A proposed 18-storey residential tower on St. Paul Street in downtown Kelowna will be constructed using mass timber, according to applications recently submitted to city planners. The city announced earlier this year that it was partnering with non-profit developer Housing Okanagan Foundation on the project for middle-income earners. Now a development permit and variance applications have been submitted for the property at 1428 St. Paul St. “If completed today, it would be the tallest mass timber residential building in Canada,” according to the application from project architect Lang Wilson Practice in Architecture Culture. “The use of mass timber also offers significant reductions in embodied carbon emissions. “This design aligns with the provincial and federal housing objectives while also incubating a building construction methodology that creates local manufacturing jobs.” Above the three-storey podium will be 15 residential floors and a rooftop terrace for all tenants.

The BCIT School of Construction and the Environment offers two Associate Certificate programs designed to support workforce development in the North American lumber and sawmill sector:

The BCIT School of Construction and the Environment offers two Associate Certificate programs designed to support workforce development in the North American lumber and sawmill sector:

In this newsletter you’ll find these stories and more:

In this newsletter you’ll find these stories and more:

Washington, D.C. – When most people think of ironworkers, mass timber is not the first thing that comes to mind. But that perception is changing fast. The International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers (Iron Workers), is proving that ironworkers are not only part of the mass timber conversation, but they are the best equipped trade to erect these projects. From landmark projects like the Walmart Headquarters in Arkansas, erected by Iron Workers’ signatory contractor Foust Fab & Erectors, to countless hybrid timber-and-steel structures across the United States and Canada, ironworkers are quietly setting the standard for mass timber erection. Ironworkers have proven that their structural steel expertise, efficiency, and safety culture make them the #1 choice for this growing market. …Our mass timber training is in partnership with WoodWorks, and therefore, third-party validated,” said Iron Workers Executive Director of Apprenticeship and Training James Owens.

Washington, D.C. – When most people think of ironworkers, mass timber is not the first thing that comes to mind. But that perception is changing fast. The International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers (Iron Workers), is proving that ironworkers are not only part of the mass timber conversation, but they are the best equipped trade to erect these projects. From landmark projects like the Walmart Headquarters in Arkansas, erected by Iron Workers’ signatory contractor Foust Fab & Erectors, to countless hybrid timber-and-steel structures across the United States and Canada, ironworkers are quietly setting the standard for mass timber erection. Ironworkers have proven that their structural steel expertise, efficiency, and safety culture make them the #1 choice for this growing market. …Our mass timber training is in partnership with WoodWorks, and therefore, third-party validated,” said Iron Workers Executive Director of Apprenticeship and Training James Owens.

ORONO, Maine — At the

ORONO, Maine — At the

FINLAND — Scientists are investigating the use of nanocellulose-based porous foam materials in stimuli-responsive smart packaging, water purification, and wireless communications. The doctoral dissertation of Mohammad Karzarjeddi at the University of Oulu, Finland, highlights how cellulose applications can help reduce reliance on fossil-based materials. Stimulus-responsive materials react to external cues, which allows for intelligent and active packaging that adapts to humidity, temperature, light, and pH. Karzarjeddi’s

FINLAND — Scientists are investigating the use of nanocellulose-based porous foam materials in stimuli-responsive smart packaging, water purification, and wireless communications. The doctoral dissertation of Mohammad Karzarjeddi at the University of Oulu, Finland, highlights how cellulose applications can help reduce reliance on fossil-based materials. Stimulus-responsive materials react to external cues, which allows for intelligent and active packaging that adapts to humidity, temperature, light, and pH. Karzarjeddi’s  Air New Zealand has unveiled Hangar 4, a state-of-the-art aircraft maintenance facility that represents one of the airline’s most significant infrastructure investments. …Designed to serve the next 50 years of aviation, the new facility positions Air New Zealand at the forefront of modern fleet maintenance as it prepares for the arrival of next-generation aircraft. At 10,000 square metres, 35 metres high and 98 metres wide, Hangar 4’s scale allows Air New Zealand engineers to service a Boeing 787-9 Dreamliner and two Airbus A320/A321s simultaneously, supported by an additional 5000 square metres of specialist workshops and engineering spaces. Hangar 4 … is the largest single-span timber arch aircraft hangar in the southern hemisphere. Timber was chosen for its lighter weight, ability to be sourced sustainably – from plantations in Nelson and Wodonga – and for its performance in a coastal environment. …Prefabricated trusses, each weighing 38 tonnes, were built in 25-metre sections, assembled on site and lifted into place…

Air New Zealand has unveiled Hangar 4, a state-of-the-art aircraft maintenance facility that represents one of the airline’s most significant infrastructure investments. …Designed to serve the next 50 years of aviation, the new facility positions Air New Zealand at the forefront of modern fleet maintenance as it prepares for the arrival of next-generation aircraft. At 10,000 square metres, 35 metres high and 98 metres wide, Hangar 4’s scale allows Air New Zealand engineers to service a Boeing 787-9 Dreamliner and two Airbus A320/A321s simultaneously, supported by an additional 5000 square metres of specialist workshops and engineering spaces. Hangar 4 … is the largest single-span timber arch aircraft hangar in the southern hemisphere. Timber was chosen for its lighter weight, ability to be sourced sustainably – from plantations in Nelson and Wodonga – and for its performance in a coastal environment. …Prefabricated trusses, each weighing 38 tonnes, were built in 25-metre sections, assembled on site and lifted into place…