Prime Minister Carney says Canada is not pursuing a free trade deal with China, as President Trump threatens 100% tariffs. In other Business news: BC Premier Eby said there are no quick fixes for forestry; Western Forest Products extends its Chemainus mill curtailment; Atli Resources’ Jonathan Lok reacts to BC chip mill closure; and Ontario workers call for action on the Ear Falls and Ignace sawmill closures.

Prime Minister Carney says Canada is not pursuing a free trade deal with China, as President Trump threatens 100% tariffs. In other Business news: BC Premier Eby said there are no quick fixes for forestry; Western Forest Products extends its Chemainus mill curtailment; Atli Resources’ Jonathan Lok reacts to BC chip mill closure; and Ontario workers call for action on the Ear Falls and Ignace sawmill closures.

In Forestry news: a 60-year trend analysis points to fewer fires but greater destruction in Canada’s forests; Drax launches a biomass tracker to boost fibre transparency; New Mexico lawmakers seek exemption from the Roadless Rule rollback; and Minnesota releases its annual forest health report. Meanwhile: after 10 years Frank Varga is stepping down at Burns Lake Community Forest; and Revelstoke Community Forest’s Kevin Bollefer addresses stigma around cutting blocks.

Finally, WorkSafeBC updates measures to manage all types of combustible dusts.

Kelly McCloskey, Tree Frog News Editor

Canada has “no intention” of pursuing a free trade deal with China, Prime Minister Carney said, after US President Trump threatened to slap punitive tariffs on Ottawa. Carney said that the country respects its obligations under the Canada-US-Mexico trade agreement, known as CUSMA in Canada and the USMCA in the US, and will not pursue a free trade agreement without notifying the other two parties. Carney’s remarks come after Trump threatened to put a 100% tariff on Canadian exports if Ottawa “makes a deal” with Beijing. …Treasury Secretary Scott Bessent also echoed Trump’s sentiments on Canada and China, saying that the UScould not “let Canada become an opening that the Chinese pour their cheap goods into the US.” …Carney said: “What we have done with China is to rectify some issues that have developed in the last couple of years,” adding that the deal was “entirely consistent with CUSMA.”

Canada has “no intention” of pursuing a free trade deal with China, Prime Minister Carney said, after US President Trump threatened to slap punitive tariffs on Ottawa. Carney said that the country respects its obligations under the Canada-US-Mexico trade agreement, known as CUSMA in Canada and the USMCA in the US, and will not pursue a free trade agreement without notifying the other two parties. Carney’s remarks come after Trump threatened to put a 100% tariff on Canadian exports if Ottawa “makes a deal” with Beijing. …Treasury Secretary Scott Bessent also echoed Trump’s sentiments on Canada and China, saying that the UScould not “let Canada become an opening that the Chinese pour their cheap goods into the US.” …Carney said: “What we have done with China is to rectify some issues that have developed in the last couple of years,” adding that the deal was “entirely consistent with CUSMA.”

The curtailment of the Chemainus sawmill will continue through to at least the end of 2026, Western Forest Products announced on Jan. 23. WFP spokesperson Babita Khunkhun said the Chemainus mill, which has been curtailed since June, continues to face persistently weak market demand and ongoing log supply challenges that do not support the economic operation of the mill. She said these conditions are not expected to change in the near term at the mill, which employs approximately 150 workers when in operation. “We are also implementing short-term curtailments at our Saltair and Ladysmith sawmills,” Khunkhun said. …“Where possible, we will work with employees to facilitate employment opportunities at other locations,” she said. …“Beginning in February, the Ladysmith sawmill plans to take a minimum two-week operating curtailment and the Saltair sawmill plans to take a two-week operating curtailment. The curtailments are in response to persistently weak market conditions.

The curtailment of the Chemainus sawmill will continue through to at least the end of 2026, Western Forest Products announced on Jan. 23. WFP spokesperson Babita Khunkhun said the Chemainus mill, which has been curtailed since June, continues to face persistently weak market demand and ongoing log supply challenges that do not support the economic operation of the mill. She said these conditions are not expected to change in the near term at the mill, which employs approximately 150 workers when in operation. “We are also implementing short-term curtailments at our Saltair and Ladysmith sawmills,” Khunkhun said. …“Where possible, we will work with employees to facilitate employment opportunities at other locations,” she said. …“Beginning in February, the Ladysmith sawmill plans to take a minimum two-week operating curtailment and the Saltair sawmill plans to take a two-week operating curtailment. The curtailments are in response to persistently weak market conditions.

KENORA — Ontario New Democrats and union leaders say government should find ways to keep mills in Ear Falls, Ignace and elsewhere open, but with more worker involvement. “The bottom line is that when things are run on the corporate bottom lines only, communities get left behind, workers lose jobs, profits go out and the problems stay in the community,” said Luke Hildebrand, president of the NDP’s Kenora–Rainy River constituency association. “So the only long-term solution is workers having a stake in the future and not just a paycheque.” Hildebrand noted a petition calling on governments to “take immediate action to reopen the Ear Falls sawmill and stop the shutdown of Ignace sawmill” has gathered about 300 signatures. It also calls for establishment of a “forestry job protection task force,” development of “a unified provincial–federal strategy to ensure that Canadian lumber is used in Canadian homes” and support for worker equity in mills.

KENORA — Ontario New Democrats and union leaders say government should find ways to keep mills in Ear Falls, Ignace and elsewhere open, but with more worker involvement. “The bottom line is that when things are run on the corporate bottom lines only, communities get left behind, workers lose jobs, profits go out and the problems stay in the community,” said Luke Hildebrand, president of the NDP’s Kenora–Rainy River constituency association. “So the only long-term solution is workers having a stake in the future and not just a paycheque.” Hildebrand noted a petition calling on governments to “take immediate action to reopen the Ear Falls sawmill and stop the shutdown of Ignace sawmill” has gathered about 300 signatures. It also calls for establishment of a “forestry job protection task force,” development of “a unified provincial–federal strategy to ensure that Canadian lumber is used in Canadian homes” and support for worker equity in mills.

ST. LOUIS — What is the life cycle of a building? Each year, in the United States, new home construction accounts for 50 million tons of carbon emissions. The majority stem from harvesting, manufacturing and transporting building materials — from lumber and masonry to glass and tile to roofing and mechanical systems. But what happens at the end of the cycle? When a building is no longer inhabitable or needed, what happens to all the energy invested in those materials? “It’s demolished,” Hongxi Yin said. “It goes to the landfill.” Yin, an expert on sustainable construction, is the InCEES professor in advanced building systems and architectural design in the Sam Fox School of Design & Visual Arts at Washington University in St. Louis. Over the last decade, he has led a series of research studios exploring ways to improve building efficiency, supply chains and construction processes.

ST. LOUIS — What is the life cycle of a building? Each year, in the United States, new home construction accounts for 50 million tons of carbon emissions. The majority stem from harvesting, manufacturing and transporting building materials — from lumber and masonry to glass and tile to roofing and mechanical systems. But what happens at the end of the cycle? When a building is no longer inhabitable or needed, what happens to all the energy invested in those materials? “It’s demolished,” Hongxi Yin said. “It goes to the landfill.” Yin, an expert on sustainable construction, is the InCEES professor in advanced building systems and architectural design in the Sam Fox School of Design & Visual Arts at Washington University in St. Louis. Over the last decade, he has led a series of research studios exploring ways to improve building efficiency, supply chains and construction processes.

Canada’s wildfire seasons are growing longer, larger and more destructive, according to a six-decade analysis of fire records by the federal government’s Canadian Forest Service. The study shows the trend isn’t being driven by more frequent fires but by a smaller number of increasingly large wildfires that are burning more land than in the past, reinforcing a trend federal scientists first identified years ago. In 2019, fire scientists with Natural Resources Canada published a study that suggested wildfire activity across the country had

Canada’s wildfire seasons are growing longer, larger and more destructive, according to a six-decade analysis of fire records by the federal government’s Canadian Forest Service. The study shows the trend isn’t being driven by more frequent fires but by a smaller number of increasingly large wildfires that are burning more land than in the past, reinforcing a trend federal scientists first identified years ago. In 2019, fire scientists with Natural Resources Canada published a study that suggested wildfire activity across the country had

It’s pretty bold to make the theme of this year’s BC Natural Resources Forum “momentum for continued growth.” What growth are we continuing? We’ve lost a bunch more mills here in the north and the industry is on the ropes with Donald Trump’s tariffs. If anything the momentum has been in the opposite direction. The momentum is heading towards catastrophic decline. At least with forestry. And we can’t let that happen. We need the pulp mills in Prince George and we need our forest industry. …We need to rethink what we are doing and find a way to do things better — and cheaper. …One direction we can move in is we start thinning the plantations close to town. …Unfortunately, BC Timber Sales is not committed to this idea. …As far as anyone can tell, they believe thinning will reduce the Annual Allowable Cut.

It’s pretty bold to make the theme of this year’s BC Natural Resources Forum “momentum for continued growth.” What growth are we continuing? We’ve lost a bunch more mills here in the north and the industry is on the ropes with Donald Trump’s tariffs. If anything the momentum has been in the opposite direction. The momentum is heading towards catastrophic decline. At least with forestry. And we can’t let that happen. We need the pulp mills in Prince George and we need our forest industry. …We need to rethink what we are doing and find a way to do things better — and cheaper. …One direction we can move in is we start thinning the plantations close to town. …Unfortunately, BC Timber Sales is not committed to this idea. …As far as anyone can tell, they believe thinning will reduce the Annual Allowable Cut.

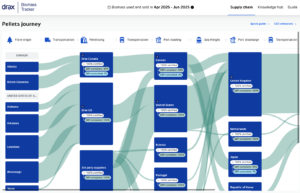

Drax launched its Biomass Tracker, a new digital tool that provides greater visibility into the journey our woody biomass takes through the company’s global supply chain. The interactive tool shows the countries and states where Drax sources its biomass, the types of fibre used in Drax’s own woody biomass, how it is transported, and the carbon associated with each stage of its journey to Drax Power Station or to third-party customers. It also includes data on independent sustainability certifications, helping to strengthen accountability across the sector. The Biomass Tracker uses quarterly real-world data presented through an interactive Sankey diagram, allowing users to explore each stage of the supply chain from fibre origin (for Drax-own pellets), pelletising to transport, storage and use. …The tool is available to access on

Drax launched its Biomass Tracker, a new digital tool that provides greater visibility into the journey our woody biomass takes through the company’s global supply chain. The interactive tool shows the countries and states where Drax sources its biomass, the types of fibre used in Drax’s own woody biomass, how it is transported, and the carbon associated with each stage of its journey to Drax Power Station or to third-party customers. It also includes data on independent sustainability certifications, helping to strengthen accountability across the sector. The Biomass Tracker uses quarterly real-world data presented through an interactive Sankey diagram, allowing users to explore each stage of the supply chain from fibre origin (for Drax-own pellets), pelletising to transport, storage and use. …The tool is available to access on

The Minnesota Department of Natural Resources aerially surveyed more than 13.5 million acres last year, checking for forest damage across the state’s forestland. Its findings are included in the recently released 2025 Forest Health Annual Report. Brian Schwingle, forest health program coordinator, said the annual survey and report is important because it tracks trends and reveals what is impacting trees, allowing the managers to make decisions for healthier, more resilient forests. “The two biggest tree health stories in 2025 in Minnesota were the derecho, the big blowdown in Bemidji, and the three big wildfires in northeast Minnesota in May,” he said, noting prior spruce budworm damage helped fuel the fires. In July, a derecho damaged 11,600 acres in and around Bemidji. Derecho, a Spanish word for straight, is a widespread, straight-line windstorm associated with a band of fast-moving thunderstorms. They can leave serious damage in their wake.

The Minnesota Department of Natural Resources aerially surveyed more than 13.5 million acres last year, checking for forest damage across the state’s forestland. Its findings are included in the recently released 2025 Forest Health Annual Report. Brian Schwingle, forest health program coordinator, said the annual survey and report is important because it tracks trends and reveals what is impacting trees, allowing the managers to make decisions for healthier, more resilient forests. “The two biggest tree health stories in 2025 in Minnesota were the derecho, the big blowdown in Bemidji, and the three big wildfires in northeast Minnesota in May,” he said, noting prior spruce budworm damage helped fuel the fires. In July, a derecho damaged 11,600 acres in and around Bemidji. Derecho, a Spanish word for straight, is a widespread, straight-line windstorm associated with a band of fast-moving thunderstorms. They can leave serious damage in their wake.