US financial markets pull back, oil prices surge and mortgage rates jump in response to Iran conflict. In related news: the Middle East crisis threatens Finland’s forestry exports, and US furniture importers. In Business news: Canada announced $13M in tariff funding for Kalesnikoff Lumber and 8 others; New Brunswick’s royalty rate change cost $45M; and Wisconsin seeks to strengthen its forest industry. Meanwhile: Canada signs aboriginal rights deal with Musqueam Indian Band encompassing Vancouver; and BC Premier Eby loses key staffer on DRIPA law.

US financial markets pull back, oil prices surge and mortgage rates jump in response to Iran conflict. In related news: the Middle East crisis threatens Finland’s forestry exports, and US furniture importers. In Business news: Canada announced $13M in tariff funding for Kalesnikoff Lumber and 8 others; New Brunswick’s royalty rate change cost $45M; and Wisconsin seeks to strengthen its forest industry. Meanwhile: Canada signs aboriginal rights deal with Musqueam Indian Band encompassing Vancouver; and BC Premier Eby loses key staffer on DRIPA law.

In Wood Product news: Canada Wood Group highlights Premier Eby’s trip to India and other wood market news; University of BC opens six-storey mass timber Gateway Health building; and Oregon’s Mass Timber Coalition is featured on ‘All Access with Andy Garcia’. In Forestry news: WWF calls out Canada on biodiversity funding; Prince Edward Island’s auditor general gives province a failing grade on forest management; and BC truck drivers have the most injury claims—and driver fatigue is a contributing factor.

Finally, ERA’s Kevin Mason on forest product markets and tariffs post US Supreme Court-ruling.

Kelly McCloskey, Tree Frog News Editor

Twenty years after spinning out Canfor Pulp Products as a separate entity, Canfor Corp. plans to bring it back into the fold to prevent the subsidiary from sinking. …Since December, its stock has plunged to about $0.50 per share. A March 6 shareholder vote on a plan of arrangement is just one of the vital signs indicating how bad 2025 was for the forestry sector in general, and BC forestry companies in particular. …But B.C. has been particularly hard hit with sawmill and pulp mill closures due to its fibre constraints and higher operating costs. The most recent high-profile mill closure in BC was the Domtar pulp mill in Crofton at the end of December. BC pulp mills rely on wood chips from sawmills to produce pulp. But so many sawmills have permanently shuttered in B.C. in the last few years that pulp mills now struggle to find enough fibre to run their mills.

Twenty years after spinning out Canfor Pulp Products as a separate entity, Canfor Corp. plans to bring it back into the fold to prevent the subsidiary from sinking. …Since December, its stock has plunged to about $0.50 per share. A March 6 shareholder vote on a plan of arrangement is just one of the vital signs indicating how bad 2025 was for the forestry sector in general, and BC forestry companies in particular. …But B.C. has been particularly hard hit with sawmill and pulp mill closures due to its fibre constraints and higher operating costs. The most recent high-profile mill closure in BC was the Domtar pulp mill in Crofton at the end of December. BC pulp mills rely on wood chips from sawmills to produce pulp. But so many sawmills have permanently shuttered in B.C. in the last few years that pulp mills now struggle to find enough fibre to run their mills. The head of B.C.’s Declaration Act Secretariat has left government on the eve of Premier David Eby’s move to change the landmark law to address court rulings that threaten private property rights. Jessica Wood, the province’s first Indigenous deputy minister, announced late last week she was departing the secretariat. “The Declaration Act was the first legislation in Canada to require consideration and alignment of provincial law with the United Nations Declaration on the Rights of Indigenous Peoples in consultation and cooperation with Indigenous Peoples,” Wood said in a post on

The head of B.C.’s Declaration Act Secretariat has left government on the eve of Premier David Eby’s move to change the landmark law to address court rulings that threaten private property rights. Jessica Wood, the province’s first Indigenous deputy minister, announced late last week she was departing the secretariat. “The Declaration Act was the first legislation in Canada to require consideration and alignment of provincial law with the United Nations Declaration on the Rights of Indigenous Peoples in consultation and cooperation with Indigenous Peoples,” Wood said in a post on

New Brunswick royalty revenues have plummeted by $45 million. It’s a figure that has forestry royalties on track to come in at an historic low in the current fiscal year. And it was a decision to significantly cut royalty rates made quietly by the Holt government last July that’s behind it. That’s as the government suggests it’s a move that’s successfully sheltered the industry from curtailments and closures that are being felt across the country. …The province moved to overhaul timber royalty rates in 2022 after acknowledging its former policy of charging forestry companies a flat rate for wood cut in public forests had failed to take advantage of a two-year explosion in international lumber prices. A new system created under the former Higgs government allowed for rates to rise and fall with the prices of various wood-based commodities. “As forest product markets improve in the future, royalty rates will index upwards,” Herron said.

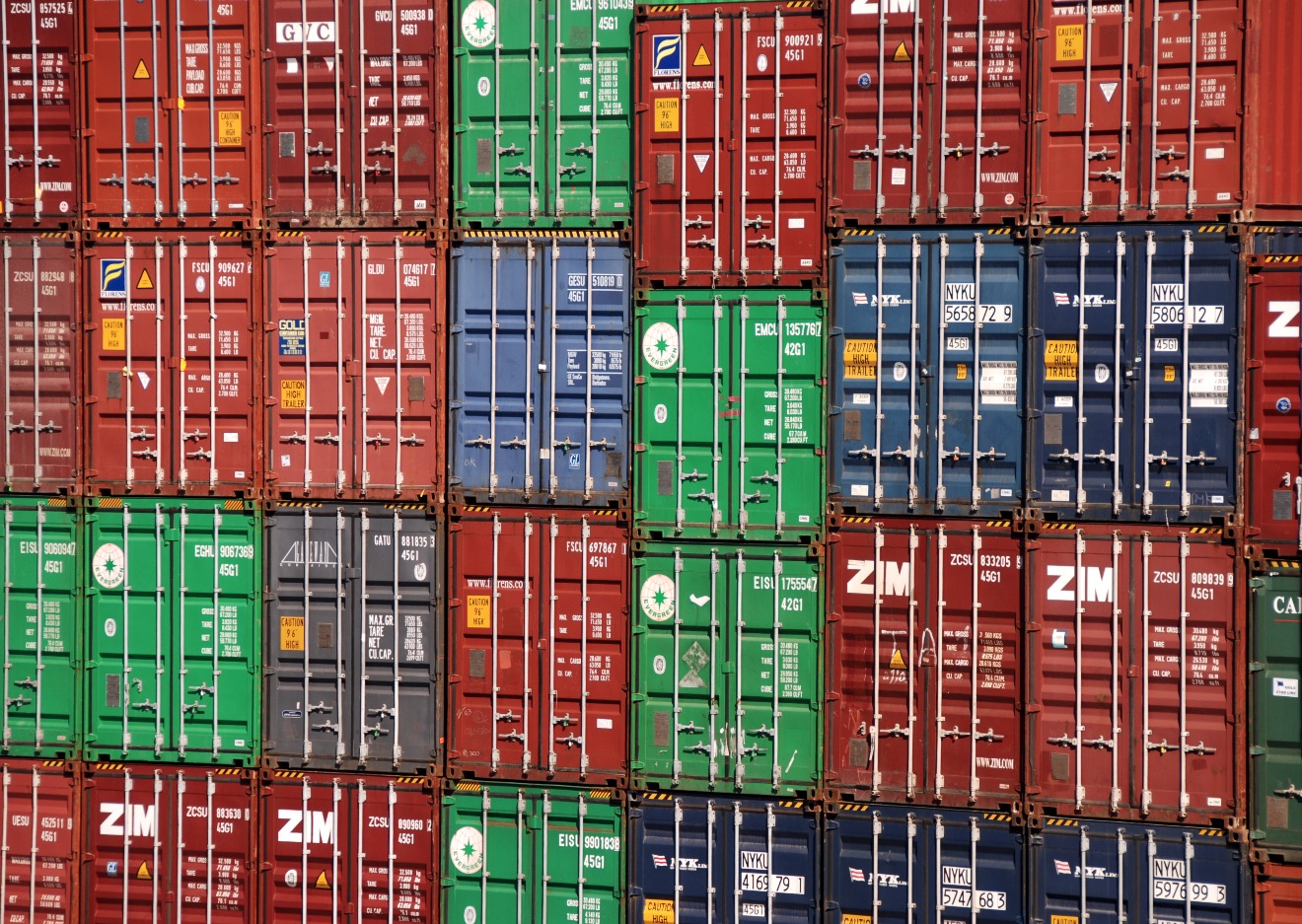

New Brunswick royalty revenues have plummeted by $45 million. It’s a figure that has forestry royalties on track to come in at an historic low in the current fiscal year. And it was a decision to significantly cut royalty rates made quietly by the Holt government last July that’s behind it. That’s as the government suggests it’s a move that’s successfully sheltered the industry from curtailments and closures that are being felt across the country. …The province moved to overhaul timber royalty rates in 2022 after acknowledging its former policy of charging forestry companies a flat rate for wood cut in public forests had failed to take advantage of a two-year explosion in international lumber prices. A new system created under the former Higgs government allowed for rates to rise and fall with the prices of various wood-based commodities. “As forest product markets improve in the future, royalty rates will index upwards,” Herron said. The escalating crisis in the Middle East could extend transport times for Finnish forest industry products to Asia by several weeks. At the same time, freight costs may rise, and container availability could become increasingly uncertain. Iran has announced the closure of the Strait of Hormuz. According to international reporting, several major shipping lines have also paused or reduced traffic through the Suez Canal, redirecting vessels around Africa via the Cape of Good Hope on routes to Asia. The Strait of Hormuz is a critical artery for global oil trade, and disruptions there primarily push up energy prices. For Finland’s forest industry, however, access through the Suez Canal is more directly decisive. Approximately 20 percent of the forest industry’s exports go to Asia, and the majority of those shipments pass through the Suez Canal, says Maarit Lindström, Director and Chief Economist at Metsäteollisuus ry.

The escalating crisis in the Middle East could extend transport times for Finnish forest industry products to Asia by several weeks. At the same time, freight costs may rise, and container availability could become increasingly uncertain. Iran has announced the closure of the Strait of Hormuz. According to international reporting, several major shipping lines have also paused or reduced traffic through the Suez Canal, redirecting vessels around Africa via the Cape of Good Hope on routes to Asia. The Strait of Hormuz is a critical artery for global oil trade, and disruptions there primarily push up energy prices. For Finland’s forest industry, however, access through the Suez Canal is more directly decisive. Approximately 20 percent of the forest industry’s exports go to Asia, and the majority of those shipments pass through the Suez Canal, says Maarit Lindström, Director and Chief Economist at Metsäteollisuus ry.  WASHINGTON — The widening conflict in the Middle East following joint U.S.-Israeli strikes against Iran is introducing fresh uncertainty into global markets, with potential downstream effects for furniture importers, who despite relying more heavily on Asia-based sourcing than directly in the region are still exposed to volatility across the global supply chain. Analysts told Reuters that a broader regional conflict could disrupt global trade routes, supply chains and commodity prices, all of which have implications downstream for furniture importers by heaping pressure on both costs and capacity. Three potential effects of the ongoing unrest in the Middle East that could spill over for furniture companies include higher fuel costs and landed container prices, container capacity pressures, and risks and longer-term supply chain strains. Over the longer term, the conflict underscores the need to reassess geographic concentration risk.

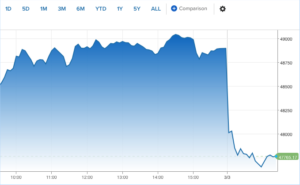

WASHINGTON — The widening conflict in the Middle East following joint U.S.-Israeli strikes against Iran is introducing fresh uncertainty into global markets, with potential downstream effects for furniture importers, who despite relying more heavily on Asia-based sourcing than directly in the region are still exposed to volatility across the global supply chain. Analysts told Reuters that a broader regional conflict could disrupt global trade routes, supply chains and commodity prices, all of which have implications downstream for furniture importers by heaping pressure on both costs and capacity. Three potential effects of the ongoing unrest in the Middle East that could spill over for furniture companies include higher fuel costs and landed container prices, container capacity pressures, and risks and longer-term supply chain strains. Over the longer term, the conflict underscores the need to reassess geographic concentration risk. US equities tumbled on Tuesday, undoing a Monday equity comeback, as oil prices spiked again and traders began to worry the U.S.-Iran conflict could drag on longer than anticipated. The Dow Jones Industrial Average lost 1,238 points, or 2.5%. If that holds, it would mark the blue-chip index’s first 1,000-point decline since April 10, 2025. The S&P 500 slipped 2.2%, while the Nasdaq Composite was down 2.3%. Brent crude oil, the international benchmark, topped $84 a barrel, up 8% Tuesday following a 6% spike Monday. WTI crude jumped 8% to above $77 a barrel after a 6% jump as well on Monday. Iranian Revolutionary Guard commander said the Strait of Hormuz — the world’s most vital transit route for crude oil — is closed and that Iran would set ablaze ships attempting the route, Reuters reported, citing Iranian media.

US equities tumbled on Tuesday, undoing a Monday equity comeback, as oil prices spiked again and traders began to worry the U.S.-Iran conflict could drag on longer than anticipated. The Dow Jones Industrial Average lost 1,238 points, or 2.5%. If that holds, it would mark the blue-chip index’s first 1,000-point decline since April 10, 2025. The S&P 500 slipped 2.2%, while the Nasdaq Composite was down 2.3%. Brent crude oil, the international benchmark, topped $84 a barrel, up 8% Tuesday following a 6% spike Monday. WTI crude jumped 8% to above $77 a barrel after a 6% jump as well on Monday. Iranian Revolutionary Guard commander said the Strait of Hormuz — the world’s most vital transit route for crude oil — is closed and that Iran would set ablaze ships attempting the route, Reuters reported, citing Iranian media. After falling below 6%, matching their lowest level in several years, mortgage rates reversed course Monday, hitting their highest point in two weeks. The average rate on the popular 30-year fixed loan rose 13 basis points to 6.12%, according to Mortgage News Daily. It had fallen to a recent low of 5.99% on Feb. 23 and pretty much sat there all week. The drop was welcome news as the all-important spring housing market gets underway. Potential buyers have been sidelined by high home prices and concerns over the broader economy. Mortgage rates crossing into the 5% range broke an emotional barrier for some, suggesting buyers might jump at the opportunity. Mortgage rates loosely follow the yield on the U.S. 10-year Treasury, which rose back above 4% on Monday. The growing conflict with Iran caused a spike in oil prices, raising inflation worries and pushing yields higher.

After falling below 6%, matching their lowest level in several years, mortgage rates reversed course Monday, hitting their highest point in two weeks. The average rate on the popular 30-year fixed loan rose 13 basis points to 6.12%, according to Mortgage News Daily. It had fallen to a recent low of 5.99% on Feb. 23 and pretty much sat there all week. The drop was welcome news as the all-important spring housing market gets underway. Potential buyers have been sidelined by high home prices and concerns over the broader economy. Mortgage rates crossing into the 5% range broke an emotional barrier for some, suggesting buyers might jump at the opportunity. Mortgage rates loosely follow the yield on the U.S. 10-year Treasury, which rose back above 4% on Monday. The growing conflict with Iran caused a spike in oil prices, raising inflation worries and pushing yields higher. Real estate professionals active in the Los Angeles market are bracing themselves for another wave of tariff-induced uncertainty following the US Supreme Court’s ruling. …Despite the Feb. 20 ruling, President Donald Trump has been adamant that he will find other avenues to impose his tariffs. Trump’s tariff policies have already caused upheaval for local businesses, and now the country’s heightened situation with tariffs will further disrupt L.A.’s real estate market, according to experts across development, manufacturing and finance. “This is a very shifting landscape for American companies,” said Ken Calligar, founder of RSG 3•D. …Garret Weyand, at Cedar Street Partners, said, “If costs are too high because of these tariffs, then projects don’t get built.” Banks will likely make borrowers increase the amount of equity so that the bank is covered in the event tariffs and inflation raise project costs.

Real estate professionals active in the Los Angeles market are bracing themselves for another wave of tariff-induced uncertainty following the US Supreme Court’s ruling. …Despite the Feb. 20 ruling, President Donald Trump has been adamant that he will find other avenues to impose his tariffs. Trump’s tariff policies have already caused upheaval for local businesses, and now the country’s heightened situation with tariffs will further disrupt L.A.’s real estate market, according to experts across development, manufacturing and finance. “This is a very shifting landscape for American companies,” said Ken Calligar, founder of RSG 3•D. …Garret Weyand, at Cedar Street Partners, said, “If costs are too high because of these tariffs, then projects don’t get built.” Banks will likely make borrowers increase the amount of equity so that the bank is covered in the event tariffs and inflation raise project costs. Visit Canada Wood’s Market News for these stories and more:

Visit Canada Wood’s Market News for these stories and more: VANCOUVER — UBC’s newest building, Gateway Health, is opening as a hub for student health, interdisciplinary teaching and collaborative research. The 270,550-square-foot building gives a purpose-built home to the school of nursing, consolidates kinesiology programs from eight campus locations, and centralizes student health and wellbeing services for the first time. …

VANCOUVER — UBC’s newest building, Gateway Health, is opening as a hub for student health, interdisciplinary teaching and collaborative research. The 270,550-square-foot building gives a purpose-built home to the school of nursing, consolidates kinesiology programs from eight campus locations, and centralizes student health and wellbeing services for the first time. …

Transport truck drivers have the most injury claims for work-related crashes of any occupation in BC over the last 10 years. And driver fatigue is a contributing factor in many crashes. Developing a strategy for reducing driver fatigue is smart business. It can help save lives and reduce the risk of injuries. It can also help you meet your legal responsibilities. Use Road Safety at Work’s no-cost resources to create or enhance your fatigue management strategy. Transport truck drivers account for nearly one-quarter of all injury claims from work-related vehicle crashes in our province, according to WorkSafeBC. …A successful fatigue management strategy depends on an effective safety culture and employee engagement. Encourage drivers to report fatigue and to pull over for a short rest when they feel it. Discuss it at safety meetings. Make fatigue part of your fit for duty assessments. Emphasize the importance of adequate sleep.

Transport truck drivers have the most injury claims for work-related crashes of any occupation in BC over the last 10 years. And driver fatigue is a contributing factor in many crashes. Developing a strategy for reducing driver fatigue is smart business. It can help save lives and reduce the risk of injuries. It can also help you meet your legal responsibilities. Use Road Safety at Work’s no-cost resources to create or enhance your fatigue management strategy. Transport truck drivers account for nearly one-quarter of all injury claims from work-related vehicle crashes in our province, according to WorkSafeBC. …A successful fatigue management strategy depends on an effective safety culture and employee engagement. Encourage drivers to report fatigue and to pull over for a short rest when they feel it. Discuss it at safety meetings. Make fatigue part of your fit for duty assessments. Emphasize the importance of adequate sleep.