Webinar | Fri, Oct 31, 2025 9:00 AM PDT | Healthcare buildings are among the most complex and resource-intensive structures we design and, increasingly, they are being asked to do more. …Mass timber is emerging as a credible alternative to conventional systems for larger-scale, high-rise institutional buildings. Recent advancements in material science, manufacturing, engineering, and fire safety have made it possible to consider timber as a structural solution for complex facilities — including hospitals. Recognizing that innovation in healthcare design must be evidence-based, this collaborative study explores the feasibility of using mass timber for a 200+ bed acute care hospital. The multidisciplinary team — including KPMB Architects, PHSA (Provincial Health Services Authority of BC), Fast + Epp, Smith + Andersen, Resource Planning Group, CHM Fire, Hanscomb, AMB Planning, and EllisDon — developed and evaluated a detailed test design for a mass timber inpatient tower suited to the Canadian context.

Webinar | Fri, Oct 31, 2025 9:00 AM PDT | Healthcare buildings are among the most complex and resource-intensive structures we design and, increasingly, they are being asked to do more. …Mass timber is emerging as a credible alternative to conventional systems for larger-scale, high-rise institutional buildings. Recent advancements in material science, manufacturing, engineering, and fire safety have made it possible to consider timber as a structural solution for complex facilities — including hospitals. Recognizing that innovation in healthcare design must be evidence-based, this collaborative study explores the feasibility of using mass timber for a 200+ bed acute care hospital. The multidisciplinary team — including KPMB Architects, PHSA (Provincial Health Services Authority of BC), Fast + Epp, Smith + Andersen, Resource Planning Group, CHM Fire, Hanscomb, AMB Planning, and EllisDon — developed and evaluated a detailed test design for a mass timber inpatient tower suited to the Canadian context.

Canada is facing a housing crisis of historic proportions. With affordability slipping out of reach for millions and supply lagging far behind demand, we need bold, scalable and sustainable solutions. The federal government’s Build Canada Homes initiative is a promising start and an opportunity to scale up the use of Canadian wood in building construction.

Canada is facing a housing crisis of historic proportions. With affordability slipping out of reach for millions and supply lagging far behind demand, we need bold, scalable and sustainable solutions. The federal government’s Build Canada Homes initiative is a promising start and an opportunity to scale up the use of Canadian wood in building construction.  The October newsletter includes these headlines and more:

The October newsletter includes these headlines and more:

At the recent 2025 Vancouver Regional Construction Association (VRCA)

At the recent 2025 Vancouver Regional Construction Association (VRCA)

Construction plastics are a major source of plastic waste in the province, and they urgently need to be measured, tracked and upcycled, says a B.C. organization that promotes sustainable built environments. Canada’s Federal Plastics Registry is expanding in 2026 to include construction plastics, but industry efforts are already underway to gather data and pilot new ways of reducing and reusing them, said Vancouver-based

Construction plastics are a major source of plastic waste in the province, and they urgently need to be measured, tracked and upcycled, says a B.C. organization that promotes sustainable built environments. Canada’s Federal Plastics Registry is expanding in 2026 to include construction plastics, but industry efforts are already underway to gather data and pilot new ways of reducing and reusing them, said Vancouver-based

HUNTSVILLE — The Ontario government is investing $10 million through the Forest Sector Investment and Innovation Program to help Daiken North America upgrade its laminated board production line at its manufacturing facility in Huntsville. This investment will help the company bring a first-of-its-kind wood panel product to market, create jobs and boost productivity. As part of its plan to protect Ontario, the government is making strategic investments to help forest sector businesses adapt, compete and grow to stay resilient in the face of U.S. tariffs. …Daiken’s $70 million project will equip them to manufacture a new type of wood panel used in flooring, recreational vehicles and modular housing, while supporting 128 existing jobs and creating 10 new jobs. This made-in-Ontario forest product is the first of its kind in the world, offering a higher-performance, lower-cost alternative to imported material.

HUNTSVILLE — The Ontario government is investing $10 million through the Forest Sector Investment and Innovation Program to help Daiken North America upgrade its laminated board production line at its manufacturing facility in Huntsville. This investment will help the company bring a first-of-its-kind wood panel product to market, create jobs and boost productivity. As part of its plan to protect Ontario, the government is making strategic investments to help forest sector businesses adapt, compete and grow to stay resilient in the face of U.S. tariffs. …Daiken’s $70 million project will equip them to manufacture a new type of wood panel used in flooring, recreational vehicles and modular housing, while supporting 128 existing jobs and creating 10 new jobs. This made-in-Ontario forest product is the first of its kind in the world, offering a higher-performance, lower-cost alternative to imported material.

Mass timber is gaining momentum as a structural material that, along with many other attributes, can reduce the embodied carbon in new buildings and retrofits. Despite this potential, and widespread enthusiasm in the design community, the uptake of mass timber has been relatively slow. Architecture 2030 and Pilot Projects Collaborative’s new report,

Mass timber is gaining momentum as a structural material that, along with many other attributes, can reduce the embodied carbon in new buildings and retrofits. Despite this potential, and widespread enthusiasm in the design community, the uptake of mass timber has been relatively slow. Architecture 2030 and Pilot Projects Collaborative’s new report,  As National Forest Products Week is observed each October, the US Endowment for Forestry and Communities is highlighting one of its partner programs that supports and advances US-based manufacturing. The Endowment is administering $5 million of the USDA Forest Service’s $80 million Wood Innovation Grants program, overseeing 18 individual projects across the country. Each project includes matching funds from subaward recipients, resulting in a total impact of approximately $10 million. Together, these investments will advance wood product manufacturing, strengthen forest management and foster energy innovation for timber-producing communities. …“Our forests are only as strong as the markets that sustain them. Through programs like the Wood Innovation Grants, we’re creating new opportunities for innovation while reinforcing the resilience of both ecosystems and the communities that depend on them. Strengthening U.S. wood products manufacturing is necessary to achieve these goals.”

As National Forest Products Week is observed each October, the US Endowment for Forestry and Communities is highlighting one of its partner programs that supports and advances US-based manufacturing. The Endowment is administering $5 million of the USDA Forest Service’s $80 million Wood Innovation Grants program, overseeing 18 individual projects across the country. Each project includes matching funds from subaward recipients, resulting in a total impact of approximately $10 million. Together, these investments will advance wood product manufacturing, strengthen forest management and foster energy innovation for timber-producing communities. …“Our forests are only as strong as the markets that sustain them. Through programs like the Wood Innovation Grants, we’re creating new opportunities for innovation while reinforcing the resilience of both ecosystems and the communities that depend on them. Strengthening U.S. wood products manufacturing is necessary to achieve these goals.” While sustainable solutions are facing drastic funding cuts, mass timber as a sustainable construction material is steadily gaining traction across the US. Construction using mass timber began in 2015 in the US, and since then the number of projects has grown about 20% annually. Today, over 2,500 mass timber projects are built or in progress in the US, including corporate offices for companies such as Google, Microsoft and Under Armour. …“We have lots of tech firms and big companies that say, ‘Hey, we’re battling it out for workers. We want the best space possible,’” said Bill Parsons, COO at WoodWorks. …Legislation that promotes and programs that fund mass timber, such as the Mass Timber Federal Buildings Act and the Wood Innovations Grant Program from the USDA, are still progressing. …Studies have shown that living or working in a mass timber building improves occupants’ mental health and well-being, even lowering their blood pressure and heart rates.

While sustainable solutions are facing drastic funding cuts, mass timber as a sustainable construction material is steadily gaining traction across the US. Construction using mass timber began in 2015 in the US, and since then the number of projects has grown about 20% annually. Today, over 2,500 mass timber projects are built or in progress in the US, including corporate offices for companies such as Google, Microsoft and Under Armour. …“We have lots of tech firms and big companies that say, ‘Hey, we’re battling it out for workers. We want the best space possible,’” said Bill Parsons, COO at WoodWorks. …Legislation that promotes and programs that fund mass timber, such as the Mass Timber Federal Buildings Act and the Wood Innovations Grant Program from the USDA, are still progressing. …Studies have shown that living or working in a mass timber building improves occupants’ mental health and well-being, even lowering their blood pressure and heart rates.

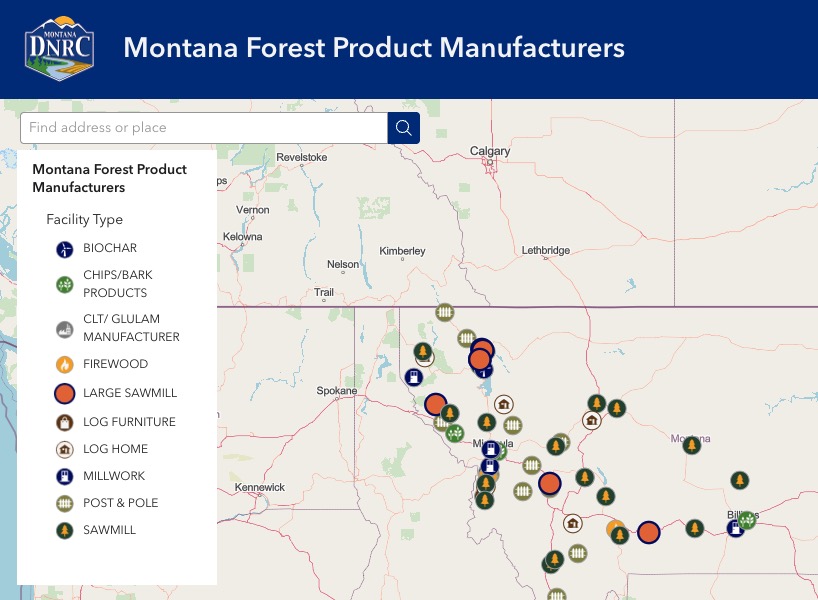

HELENA, Mont. — The Montana Department of Natural Resources and Conservation (DNRC) has launched an online interactive map showing forest product manufacturers across the state. The new tool helps landowners, contractors, and community members locate nearby mills and connect with partners for forest management and wood processing projects. Each facility listing includes details such as product types, wood species used, and company size, with direct links to their websites. “Beyond helping Montanans find nearby mills, the map highlights manufacturing capacity that supports forest restoration, fuels reduction, and local jobs,” said Marc Vessar, DNRC forest practices program manager.

HELENA, Mont. — The Montana Department of Natural Resources and Conservation (DNRC) has launched an online interactive map showing forest product manufacturers across the state. The new tool helps landowners, contractors, and community members locate nearby mills and connect with partners for forest management and wood processing projects. Each facility listing includes details such as product types, wood species used, and company size, with direct links to their websites. “Beyond helping Montanans find nearby mills, the map highlights manufacturing capacity that supports forest restoration, fuels reduction, and local jobs,” said Marc Vessar, DNRC forest practices program manager.

Understanding the differences between lyocell vs cotton becomes crucial when choosing sustainable, comfortable fabrics for your wardrobe and home. Over 68% of US consumers now prioritize eco-friendly textiles in their purchasing decisions, yet many remain confused about lyocell’s advantages over traditional cotton. This comprehensive guide reveals the exact properties, environmental impact, and performance characteristics that distinguish these two popular fabrics in 2025. …Lyocell is a regenerated cellulose fiber made from wood pulp through an innovative closed-loop manufacturing process that recovers over 99% of solvents used in production. …The choice between lyocell vs cotton depends on your priorities: sustainability goals, budget constraints, specific use applications, and care preferences. Neither fiber is universally superior—each excels in different scenarios. Choose lyocell if you prioritize: environmental sustainability, moisture-wicking performance, luxury feel, and durability. …Our sustainability analysis shows lyocell winning decisively with 78% less water usage, no pesticide requirements, and complete biodegradability.

Understanding the differences between lyocell vs cotton becomes crucial when choosing sustainable, comfortable fabrics for your wardrobe and home. Over 68% of US consumers now prioritize eco-friendly textiles in their purchasing decisions, yet many remain confused about lyocell’s advantages over traditional cotton. This comprehensive guide reveals the exact properties, environmental impact, and performance characteristics that distinguish these two popular fabrics in 2025. …Lyocell is a regenerated cellulose fiber made from wood pulp through an innovative closed-loop manufacturing process that recovers over 99% of solvents used in production. …The choice between lyocell vs cotton depends on your priorities: sustainability goals, budget constraints, specific use applications, and care preferences. Neither fiber is universally superior—each excels in different scenarios. Choose lyocell if you prioritize: environmental sustainability, moisture-wicking performance, luxury feel, and durability. …Our sustainability analysis shows lyocell winning decisively with 78% less water usage, no pesticide requirements, and complete biodegradability.  Ireland must realise the “massive opportunity” that exists as timber construction is set to triple market value and deliver climate action, Forest Industries Ireland (FII) said. The director of FII, Mark McAuley has welcomed a

Ireland must realise the “massive opportunity” that exists as timber construction is set to triple market value and deliver climate action, Forest Industries Ireland (FII) said. The director of FII, Mark McAuley has welcomed a

More companies that provide rayon, lyocell and modal to fashion brands are sourcing less from ancient and endangered forests, according to the nonprofit Canopy. Although the vast majority of cellulosic fibers are still spun from virgin materials, some of the biggest producers have been quickly adopting forest-friendly and circular materials. 70% of companies making semi-synthetic, cellulose-based fibers now exhibit green practices that reduce pressures on forests. 54% of fiber producers that the group tracked have reached the nonprofit’s favorable green rating. …Canopy uses this annual report in part to help brands make informed sourcing decisions. The use of recycled materials for such fibers is still rare, although it grew to 1.1% in 2024. Such textiles represent only 6% of the global fiber market, according to Textile Exchange. It found that fibers approved by Forest Stewardship Council (FSC) or other certification made up as much as 70 percent of cellulosic fiber market share.

More companies that provide rayon, lyocell and modal to fashion brands are sourcing less from ancient and endangered forests, according to the nonprofit Canopy. Although the vast majority of cellulosic fibers are still spun from virgin materials, some of the biggest producers have been quickly adopting forest-friendly and circular materials. 70% of companies making semi-synthetic, cellulose-based fibers now exhibit green practices that reduce pressures on forests. 54% of fiber producers that the group tracked have reached the nonprofit’s favorable green rating. …Canopy uses this annual report in part to help brands make informed sourcing decisions. The use of recycled materials for such fibers is still rare, although it grew to 1.1% in 2024. Such textiles represent only 6% of the global fiber market, according to Textile Exchange. It found that fibers approved by Forest Stewardship Council (FSC) or other certification made up as much as 70 percent of cellulosic fiber market share.

Several parliamentarians, key industry players and alternative materials start-ups in hemp, engineered bamboo and engineered timber attended an event designed to focus a spotlight on the new world of possibilities in building materials. The WWF and Forest Alliance NSW event was intended to showcase sustainable alternatives to timber products …with the protection of the proposed Great Koala National Park at the centre of conversations. The event was further by the Parliamentary Friends of Forests. Attending as exhibitors were House of Bamboo, Hemp Inside, Bamboo Society Australia, Australian Hemp Council, iHempNSW, BVN Architecture and betti & knutt. While XLAM … was originally on the list of presenters, an industry source says the pressure from forestry sources had forced the company to pull out. …Susie Russell was particularly inspired by House of Bamboo, realizing that similar products to timber can be made from bamboo, which only takes five years to grow.

Several parliamentarians, key industry players and alternative materials start-ups in hemp, engineered bamboo and engineered timber attended an event designed to focus a spotlight on the new world of possibilities in building materials. The WWF and Forest Alliance NSW event was intended to showcase sustainable alternatives to timber products …with the protection of the proposed Great Koala National Park at the centre of conversations. The event was further by the Parliamentary Friends of Forests. Attending as exhibitors were House of Bamboo, Hemp Inside, Bamboo Society Australia, Australian Hemp Council, iHempNSW, BVN Architecture and betti & knutt. While XLAM … was originally on the list of presenters, an industry source says the pressure from forestry sources had forced the company to pull out. …Susie Russell was particularly inspired by House of Bamboo, realizing that similar products to timber can be made from bamboo, which only takes five years to grow.