Prime Minister Mark Carney showed no signs of retaliating against U.S. President Donald Trump’s increased tariffs — and even suggested he’s open to removing existing tariffs if it would help Canadian industries. …”We’ve always said we will apply tariffs where they had the maximum impact on the United States and minimum impact in Canada,” said Carney when asked why Canada hasn’t fired back against the new tariff rate. Prime Minister Mark Carney said he hadn’t ‘spoken to the president in recent days’ as Canada and the US are still without a trade deal. ….”So we don’t automatically adjust. We look at what we can do for our industry that’s most effective. In some cases that will be to remove tariffs.” …Carney floating the idea of dropping tariffs is notable after Trump granted Mexico a 90-day pause on tariff hikes with the goal of signing a new deal.

President Donald Trump said the US will put a 35% tariff on some imports from Canada, escalating the tensions between two countries that have impaired one of the world’s largest trading relationships. The new rate represents an increase from the 25% tariffs Trump imposed in early March under an emergency law. …But the US administration kept in place an exemption for goods traded under the rules of the US-Mexico-Canada trade agreement. US automakers and other companies with integrated North American supply chains had pushed for that carve-out, which has allowed US importers to continue bringing in the bulk of Mexican and Canadian products without duties. Because of the USMCA exemption, the effective tariff rate on US imports of Canadian goods was around 5%. …Trump signaled that he would be open to further talks with Carney. …Hours before raising Canada’s tariffs, Trump agreed to extend current tariffs on Mexico for 90 days.

President Donald Trump said the US will put a 35% tariff on some imports from Canada, escalating the tensions between two countries that have impaired one of the world’s largest trading relationships. The new rate represents an increase from the 25% tariffs Trump imposed in early March under an emergency law. …But the US administration kept in place an exemption for goods traded under the rules of the US-Mexico-Canada trade agreement. US automakers and other companies with integrated North American supply chains had pushed for that carve-out, which has allowed US importers to continue bringing in the bulk of Mexican and Canadian products without duties. Because of the USMCA exemption, the effective tariff rate on US imports of Canadian goods was around 5%. …Trump signaled that he would be open to further talks with Carney. …Hours before raising Canada’s tariffs, Trump agreed to extend current tariffs on Mexico for 90 days.

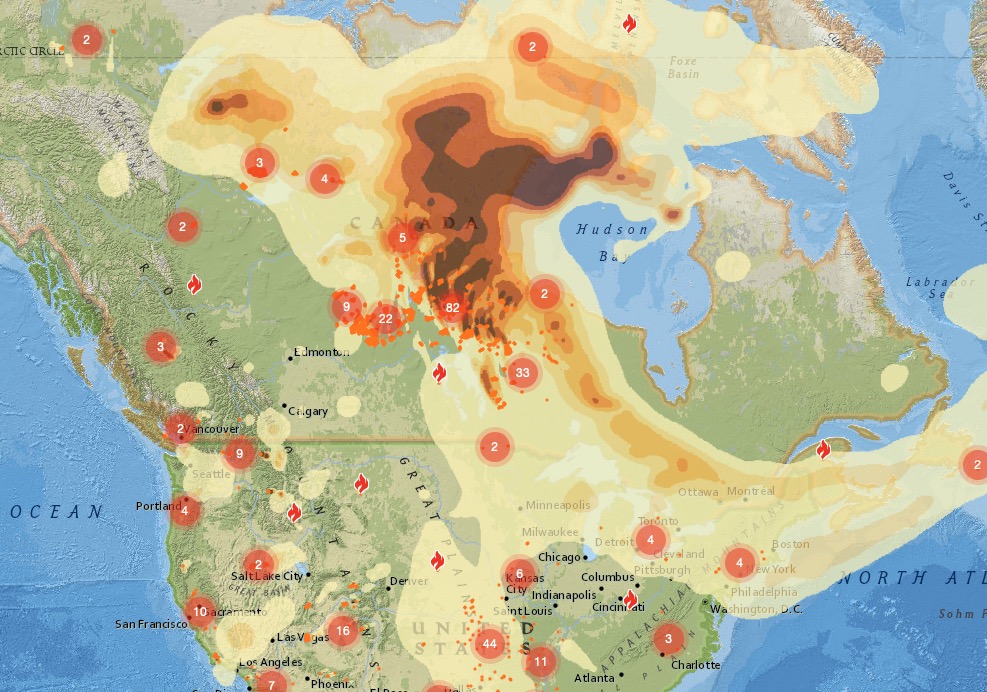

WASHINGTON — More Republican lawmakers are calling out Canada because of wildfires sending smoke billowing across the international border into their states. Wisconsin state Rep. Calvin Callahan has joined other Republican state lawmakers from Iowa, Minnesota and North Dakota in filing a formal complaint against Canada to the U.S. Environmental Protection Agency and the International Joint Commission. In a news release issued today, Callahan says that “if Canada can’t get these wildfires under control, they need to face real consequences.” He joins a chorus of Republican politicians at other levels of government who have been voicing concerns about Canada’s wildfires. Michigan Rep. Jack Bergman sent a letter to Canadian Sen. Michael MacDonald on Monday calling for stronger forest management policies and more accountability from Canadian officials. Michigan Rep. John James sent a letter to Prime Minister Mark Carney last week saying his constituents are choking on toxic wildfire smoke.

WASHINGTON — More Republican lawmakers are calling out Canada because of wildfires sending smoke billowing across the international border into their states. Wisconsin state Rep. Calvin Callahan has joined other Republican state lawmakers from Iowa, Minnesota and North Dakota in filing a formal complaint against Canada to the U.S. Environmental Protection Agency and the International Joint Commission. In a news release issued today, Callahan says that “if Canada can’t get these wildfires under control, they need to face real consequences.” He joins a chorus of Republican politicians at other levels of government who have been voicing concerns about Canada’s wildfires. Michigan Rep. Jack Bergman sent a letter to Canadian Sen. Michael MacDonald on Monday calling for stronger forest management policies and more accountability from Canadian officials. Michigan Rep. John James sent a letter to Prime Minister Mark Carney last week saying his constituents are choking on toxic wildfire smoke.

Wyoming’s few remaining lumber mills have been struggling, but a shift in federal and state timber policy might herald a new era for the industry here. Gov. Mark Gordon on Friday signed an executive order calling for an “increase of active forest management in Wyoming.” It mirrors President Donald Trump’s March 1 executive order for “immediate expansion of American timber production.” That might be the break that Wyoming logging companies and timber mills have for years been anxiously awaiting, Jenny Haider, of the Evanston-based Smith & Jones Timber Company, told Cowboy State Daily on Monday. The fourth-generation family-owned business has been going for 80 years but barely survived the past few, she said. …Trump’s order, coupled with tariffs on Canadian timber being imported into the US could be a game-changer for logging operations and mills in Wyoming. …Now, Wyoming timber companies are “using the word ‘hope’ again,” she added.

Wyoming’s few remaining lumber mills have been struggling, but a shift in federal and state timber policy might herald a new era for the industry here. Gov. Mark Gordon on Friday signed an executive order calling for an “increase of active forest management in Wyoming.” It mirrors President Donald Trump’s March 1 executive order for “immediate expansion of American timber production.” That might be the break that Wyoming logging companies and timber mills have for years been anxiously awaiting, Jenny Haider, of the Evanston-based Smith & Jones Timber Company, told Cowboy State Daily on Monday. The fourth-generation family-owned business has been going for 80 years but barely survived the past few, she said. …Trump’s order, coupled with tariffs on Canadian timber being imported into the US could be a game-changer for logging operations and mills in Wyoming. …Now, Wyoming timber companies are “using the word ‘hope’ again,” she added. President Trump’s expanded reciprocal tariffs will not apply to any products loaded onto a vessel for transport into the US before 12:01 a.m. New York time on Thursday, according to guidance issued by

President Trump’s expanded reciprocal tariffs will not apply to any products loaded onto a vessel for transport into the US before 12:01 a.m. New York time on Thursday, according to guidance issued by

A panel of appeals court judges on Thursday voiced deep skepticism with the Trump administration’s attempt to justify sweeping tariffs based on a national emergency. The US Court of Appeals for the Federal Circuit is hearing arguments Thursday over whether Trump’s sweeping tariffs are lawful. A group of small businesses and a coalition of states are asking the appeals court to invalidate the bulk of Trump’s tariffs, arguing that Trump overstepped his power when he invoked the rarely used International Emergency Economic Powers Act (IEEPA). At the start of Thursday’s hearing, judges on the appeals court panel questioned why Trump is relying on a law that has never been used to justify tariffs, saying that the law itself never mentions the word “tariffs” and voicing concern that the president justifying the unilateral action based on an emergency could amount to “the death knell of the Constitution.”

A panel of appeals court judges on Thursday voiced deep skepticism with the Trump administration’s attempt to justify sweeping tariffs based on a national emergency. The US Court of Appeals for the Federal Circuit is hearing arguments Thursday over whether Trump’s sweeping tariffs are lawful. A group of small businesses and a coalition of states are asking the appeals court to invalidate the bulk of Trump’s tariffs, arguing that Trump overstepped his power when he invoked the rarely used International Emergency Economic Powers Act (IEEPA). At the start of Thursday’s hearing, judges on the appeals court panel questioned why Trump is relying on a law that has never been used to justify tariffs, saying that the law itself never mentions the word “tariffs” and voicing concern that the president justifying the unilateral action based on an emergency could amount to “the death knell of the Constitution.”

The Maine State Chamber of Commerce has been following the Trump administration’s actions on tariffs since the start of the year, said President and Chief Executive Officer Patrick Woodcock. …Woodcock said Monday that some individual companies and industries are already seeing a “dramatic impact.” For example, he said lumber product prices have increased. … In Maine, “our forest products industry is the one that is most affected with these specific industry, sector-level tariffs,” Woodcock said. The state imports 2.3 million tons of wood products annually, most of which comes from Canada, according to a Maine Forest Service

The Maine State Chamber of Commerce has been following the Trump administration’s actions on tariffs since the start of the year, said President and Chief Executive Officer Patrick Woodcock. …Woodcock said Monday that some individual companies and industries are already seeing a “dramatic impact.” For example, he said lumber product prices have increased. … In Maine, “our forest products industry is the one that is most affected with these specific industry, sector-level tariffs,” Woodcock said. The state imports 2.3 million tons of wood products annually, most of which comes from Canada, according to a Maine Forest Service  It’s been over a week since the U.S. Commerce Department confirmed that it’s nearly tripling its anti-dumping duties on Canadian lumber imports from 7.66% to 20.56% following its annual review. The response from north of the border has been apoplectic, to say the least. …In the US, several entities are worried about the hiked duties, too. The NAHB continues to sound the alarm that new duties will raise the cost of homebuilding. …”We are also urging the administration to move immediately to enter into negotiations with Canada on a new softwood lumber agreement.” …The US Lumber Coalition continues to be the loudest voice in the room in favor. …”Canada continues its relentless shipments of dumped and subsidized lumber with devastating consequences for mills, workers, and communities.” …The downstream effects of all these trade war machinations remain to be seen, though the cross-border lumber trade has already slowed down considerably.

It’s been over a week since the U.S. Commerce Department confirmed that it’s nearly tripling its anti-dumping duties on Canadian lumber imports from 7.66% to 20.56% following its annual review. The response from north of the border has been apoplectic, to say the least. …In the US, several entities are worried about the hiked duties, too. The NAHB continues to sound the alarm that new duties will raise the cost of homebuilding. …”We are also urging the administration to move immediately to enter into negotiations with Canada on a new softwood lumber agreement.” …The US Lumber Coalition continues to be the loudest voice in the room in favor. …”Canada continues its relentless shipments of dumped and subsidized lumber with devastating consequences for mills, workers, and communities.” …The downstream effects of all these trade war machinations remain to be seen, though the cross-border lumber trade has already slowed down considerably. Canada’s merchandise trade deficit widened in June to C$5.9 billion as imports grew faster than exports due to a one-time high-value oil equipment import. The deficit observed in June is the second highest on record after the deficit expanded to its largest in history in April to C$7.6 billion, when the impact of US tariffs first started to weigh. Canada’s exports to the US as a share of total exports shrank to 70% in June from 83% in the same period a year ago while its surplus with the US contracted by a half in the same period, data showed. Total imports were up 1.4% in June to C$67.6 billion from a drop of 1.6% in the prior month, Statistics Canada said. Canada’s total exports grew 0.9% in June to C$61.74 billion following an increase of 2% in May, led primarily by an increase in crude oil exports.

Canada’s merchandise trade deficit widened in June to C$5.9 billion as imports grew faster than exports due to a one-time high-value oil equipment import. The deficit observed in June is the second highest on record after the deficit expanded to its largest in history in April to C$7.6 billion, when the impact of US tariffs first started to weigh. Canada’s exports to the US as a share of total exports shrank to 70% in June from 83% in the same period a year ago while its surplus with the US contracted by a half in the same period, data showed. Total imports were up 1.4% in June to C$67.6 billion from a drop of 1.6% in the prior month, Statistics Canada said. Canada’s total exports grew 0.9% in June to C$61.74 billion following an increase of 2% in May, led primarily by an increase in crude oil exports. Lumber futures hit their highest price in three years Friday despite a home-building slump and a lackluster remodeling market. Though wood demand is tepid, traders are pricing in dramatically higher duties on lumber imports from Canada. Lumber futures for September delivery hit $695 per thousand board feet Friday, up 39% from a year ago and the highest price since summer 2022, when the price of two-by-fours was tumbling down from its pandemic surge. November futures are trading even higher, around $710. The US raised its antidumping duty Tuesday to nearly 21% from 7.7%… [and] The Commerce Department said it would impose a higher countervailing duty in the coming days. The combined rate is expected to be around 35%. …”We don’t make a tremendous amount of money on distributing lumber,” Builders FirstSource CEO Peter Jacksons told investors. “We’re not eating a 20-point increase in lumber. It’s not possible. So it will be passed through. The market will adapt.” [to access the full story a WSJ subscription is required]

Lumber futures hit their highest price in three years Friday despite a home-building slump and a lackluster remodeling market. Though wood demand is tepid, traders are pricing in dramatically higher duties on lumber imports from Canada. Lumber futures for September delivery hit $695 per thousand board feet Friday, up 39% from a year ago and the highest price since summer 2022, when the price of two-by-fours was tumbling down from its pandemic surge. November futures are trading even higher, around $710. The US raised its antidumping duty Tuesday to nearly 21% from 7.7%… [and] The Commerce Department said it would impose a higher countervailing duty in the coming days. The combined rate is expected to be around 35%. …”We don’t make a tremendous amount of money on distributing lumber,” Builders FirstSource CEO Peter Jacksons told investors. “We’re not eating a 20-point increase in lumber. It’s not possible. So it will be passed through. The market will adapt.” [to access the full story a WSJ subscription is required] VANCOUVER, BC —

VANCOUVER, BC —  NEW YORK, NY -‑ Mercer International reported second quarter 2025. In the second quarter of 2025, net loss was $86.1 million compared to $67.6 million in the same quarter of 2024 and $22.3 million in the first quarter of 2025. Mr. Juan Carlos Bueno, Chief Executive Officer, stated: “Our operating results for the second quarter of 2025 reflect the impacts of ongoing uncertainties in the global trade environment coupled with the resulting weaker dollar. This challenging backdrop contributed to weaker demand for pulp in China during the quarter. …Our lumber sales realizations in both the U.S. and Europe increased in the second quarter of 2025 as a result of lower supply and steady demand.

NEW YORK, NY -‑ Mercer International reported second quarter 2025. In the second quarter of 2025, net loss was $86.1 million compared to $67.6 million in the same quarter of 2024 and $22.3 million in the first quarter of 2025. Mr. Juan Carlos Bueno, Chief Executive Officer, stated: “Our operating results for the second quarter of 2025 reflect the impacts of ongoing uncertainties in the global trade environment coupled with the resulting weaker dollar. This challenging backdrop contributed to weaker demand for pulp in China during the quarter. …Our lumber sales realizations in both the U.S. and Europe increased in the second quarter of 2025 as a result of lower supply and steady demand.

If some banks or financial institutions have long been poised to abandon paper records, a representative to Congress is saying “Not so fast. US Rep. Mike Turner, R-Dayton, said he reintroduced his “Protecting Against Paperless and Electronic Requirement (PAPER) Act” recently. This legislation would prohibit financial institutions from abandoning paper records to use electronic bank statements. For many years, banks would print and mail monthly bank statements to all customers. For a while now, though, paper bank statements have been replaced by electronic statements. …The PAPER Act would bar financial institutions from restricting services based on a customer’s preference for paper statements, making certain that all Americans can participate in our banking system in a way that works best for them.” …In March, President Trump signed an executive order mandating that the federal government shift from paper-based payments to electronic payments.

If some banks or financial institutions have long been poised to abandon paper records, a representative to Congress is saying “Not so fast. US Rep. Mike Turner, R-Dayton, said he reintroduced his “Protecting Against Paperless and Electronic Requirement (PAPER) Act” recently. This legislation would prohibit financial institutions from abandoning paper records to use electronic bank statements. For many years, banks would print and mail monthly bank statements to all customers. For a while now, though, paper bank statements have been replaced by electronic statements. …The PAPER Act would bar financial institutions from restricting services based on a customer’s preference for paper statements, making certain that all Americans can participate in our banking system in a way that works best for them.” …In March, President Trump signed an executive order mandating that the federal government shift from paper-based payments to electronic payments.

PENSACOLA, Florida — A Beloit, Wisconsin-based general contractor will have a share in redeveloping a beachfront park in Florida. Pensacola, Florida-based The Dawson Company announced Beloit-based Corporate Contractors will be a co-developer, co-owner and investment partner in the first phase of a $200 million redevelopment of Community Maritime Park in Pensacola. Diane Hendricks, named the richest self-made woman in the US by Forbes and cofounder of ABC Supply, owns Corporate Contractors through the Hendricks Holding Company. …The first phase of construction involves two mass timber towers for the Reverb by Hard Rock Hotel and Rhythm Lofts, plans showed. The project will also have an affordable aspect, plans added. …In Wisconsin, CCI’s portfolio includes the Beloit College Powerhouse and The Grain mass timber development in Delafield. CCI is currently the owner’s representative for the $500 million Ho-Chunk Nation Casino and Convention Center underway in Beloit.

PENSACOLA, Florida — A Beloit, Wisconsin-based general contractor will have a share in redeveloping a beachfront park in Florida. Pensacola, Florida-based The Dawson Company announced Beloit-based Corporate Contractors will be a co-developer, co-owner and investment partner in the first phase of a $200 million redevelopment of Community Maritime Park in Pensacola. Diane Hendricks, named the richest self-made woman in the US by Forbes and cofounder of ABC Supply, owns Corporate Contractors through the Hendricks Holding Company. …The first phase of construction involves two mass timber towers for the Reverb by Hard Rock Hotel and Rhythm Lofts, plans showed. The project will also have an affordable aspect, plans added. …In Wisconsin, CCI’s portfolio includes the Beloit College Powerhouse and The Grain mass timber development in Delafield. CCI is currently the owner’s representative for the $500 million Ho-Chunk Nation Casino and Convention Center underway in Beloit.

The 9th American Forest Congress has

The 9th American Forest Congress has  The Trump administration has proposed drastically limiting the public’s say in how federal lands are used at a time when the president is pushing to fast-track logging, mining and oil extraction. That’s raising concerns amongst conservationists and environmental advocates, who worry that the changes could have a profound impact on Oregonians’ relationship with the lands around them. More than half the land in Oregon is federally owned, as is about 29% of land in Washington. …Under President Donald Trump, 16 federal agencies are now considering rule changes that could curtail or drastically limit this public input, which is required under the National Environmental Policy Act, known as NEPA. Those proposed changes were announced in early July. The public has until Monday to provide input on the changes for the U.S Forest Service and the Bureau of Land Management. …Data shows that public comments can make a difference.

The Trump administration has proposed drastically limiting the public’s say in how federal lands are used at a time when the president is pushing to fast-track logging, mining and oil extraction. That’s raising concerns amongst conservationists and environmental advocates, who worry that the changes could have a profound impact on Oregonians’ relationship with the lands around them. More than half the land in Oregon is federally owned, as is about 29% of land in Washington. …Under President Donald Trump, 16 federal agencies are now considering rule changes that could curtail or drastically limit this public input, which is required under the National Environmental Policy Act, known as NEPA. Those proposed changes were announced in early July. The public has until Monday to provide input on the changes for the U.S Forest Service and the Bureau of Land Management. …Data shows that public comments can make a difference.

The Washington Forest Practices Board is proposing new legislation pushed by the Washington Department of Ecology that will affect all of us financially. The Washington Forest Practices Board (FPB) is supposedly an “independent” state agency responsible for establishing rules that govern forest practices in Washington state. It’s chaired by the Commissioner of Public Lands Dave Upthegrove. …The FPB is proposing streams that are perennial with no fish should have the existing no-harvest buffers changed from 50 feet each side of the stream to 75 feet (or more). The proposal affects not only the stream buffer width, but the length of stream buffer and volume of restricted trees. Why does it affect you? All timber harvests are taxed by the state of Washington — 4% of the net log value goes back to the county the trees were harvested in. …You are affected by this proposed change in law that does nothing for fish.

The Washington Forest Practices Board is proposing new legislation pushed by the Washington Department of Ecology that will affect all of us financially. The Washington Forest Practices Board (FPB) is supposedly an “independent” state agency responsible for establishing rules that govern forest practices in Washington state. It’s chaired by the Commissioner of Public Lands Dave Upthegrove. …The FPB is proposing streams that are perennial with no fish should have the existing no-harvest buffers changed from 50 feet each side of the stream to 75 feet (or more). The proposal affects not only the stream buffer width, but the length of stream buffer and volume of restricted trees. Why does it affect you? All timber harvests are taxed by the state of Washington — 4% of the net log value goes back to the county the trees were harvested in. …You are affected by this proposed change in law that does nothing for fish.

The Nature Conservancy announced it planted 2.5 million trees in northern Minnesota this year in partnership with the U.S. Forest Service, Minnesota Department of Natural Resources and three county land departments. This is a record number for the organization, and the second consecutive year the program has planted more than 2 million tree seedlings The tree seedlings were planted on public lands—across 5,810 acres of national forest, state forest, state park and county-managed forest lands—and covered six counties, including Cook, Lake, Saint Louis, Itasca, Cass and Carlton County. The planting areas included 1.8 miles along scenic Highway 61 and 41 miles of stream, river and lakeshore that connect to Lake Superior. It also included 1,740 acres of moose habitat enhancement, completed in partnership with the Ruffed Grouse Society and Minnesota Moose Habitat Collaborative—whose tribal representation is critical in maintaining habitat for this species of cultural importance to Indigenous communities.

The Nature Conservancy announced it planted 2.5 million trees in northern Minnesota this year in partnership with the U.S. Forest Service, Minnesota Department of Natural Resources and three county land departments. This is a record number for the organization, and the second consecutive year the program has planted more than 2 million tree seedlings The tree seedlings were planted on public lands—across 5,810 acres of national forest, state forest, state park and county-managed forest lands—and covered six counties, including Cook, Lake, Saint Louis, Itasca, Cass and Carlton County. The planting areas included 1.8 miles along scenic Highway 61 and 41 miles of stream, river and lakeshore that connect to Lake Superior. It also included 1,740 acres of moose habitat enhancement, completed in partnership with the Ruffed Grouse Society and Minnesota Moose Habitat Collaborative—whose tribal representation is critical in maintaining habitat for this species of cultural importance to Indigenous communities.

Dust collection expert Robert Williamson at Nederman Corporation, commented on a video of the deadly explosions at Horizon Biofuels, in Fremont, Nebraska. “It’s only speculation at this point, but it is these types of [wood dust explosive] events where we see fatalities,” said Williamson, VP Technical Solutions and Business Development North America. “You have the primary explosion and then a bigger explosion, the whole elevator explodes, and part of the building.” After the primary event, fine dust, which is more reactive than heavier dust and tends to accumulate in hard-to-clean areas, causes a secondary explosion, which experts on the scene also believe was the case in this instance. …Wood dust explosions can happen so fast that there is no time to evacuate. “These things happen so quickly, in less than 500 milliseconds,” he said, “There’s really no way to get away. Nobody’s going to run from this.”

Dust collection expert Robert Williamson at Nederman Corporation, commented on a video of the deadly explosions at Horizon Biofuels, in Fremont, Nebraska. “It’s only speculation at this point, but it is these types of [wood dust explosive] events where we see fatalities,” said Williamson, VP Technical Solutions and Business Development North America. “You have the primary explosion and then a bigger explosion, the whole elevator explodes, and part of the building.” After the primary event, fine dust, which is more reactive than heavier dust and tends to accumulate in hard-to-clean areas, causes a secondary explosion, which experts on the scene also believe was the case in this instance. …Wood dust explosions can happen so fast that there is no time to evacuate. “These things happen so quickly, in less than 500 milliseconds,” he said, “There’s really no way to get away. Nobody’s going to run from this.” FREMONT, Neb. – Two days after a horrific explosion at a biofuels plant left a man and two girls dead, the state fire marshal told First Alert 6 the incident started with a dust fire — and was an accident. “A preliminary investigation indicates an accidental dust explosion occurred during the manufacturing process. Additional investigation efforts are currently impeded due to the instability of the structure,” the Nebraska Fire Marshal agency said in a statement Thursday afternoon. The state has completed its initial investigation of the incident at Horizon Biofuels, which manufactures wood pellets and animal bedding. Occupational Safety and Health Administration , however, remains at the scene and must — by law — complete its investigation within six months. The

FREMONT, Neb. – Two days after a horrific explosion at a biofuels plant left a man and two girls dead, the state fire marshal told First Alert 6 the incident started with a dust fire — and was an accident. “A preliminary investigation indicates an accidental dust explosion occurred during the manufacturing process. Additional investigation efforts are currently impeded due to the instability of the structure,” the Nebraska Fire Marshal agency said in a statement Thursday afternoon. The state has completed its initial investigation of the incident at Horizon Biofuels, which manufactures wood pellets and animal bedding. Occupational Safety and Health Administration , however, remains at the scene and must — by law — complete its investigation within six months. The

Arizona’s fire season keeps smoldering and flaring, thanks to a schizo monsoon and a dry winter. The 125,000-acre Dragon Bravo Fire continues to grow, with the 1,200 firefighters managing just 13% containment after nearly a month of trying. The National Weather Service had predicted a normal to wet monsoon after a bone-dry winter, based largely on sea-surface temperatures in the Pacific. But as a global warming trend driven by heat-trapping pollutants pumps energy into the atmosphere, patterns of drought, heat and storm tracks have become harder and harder to predict. So the monsoon has splashed and sputtered, with a week of storms giving way to a week of hot, dry weather – extending the fire season well into the period when fire crews would normally shift to other areas. Fortunately, the extended forecast calls for a chance the monsoon will gust back to life next week.

Arizona’s fire season keeps smoldering and flaring, thanks to a schizo monsoon and a dry winter. The 125,000-acre Dragon Bravo Fire continues to grow, with the 1,200 firefighters managing just 13% containment after nearly a month of trying. The National Weather Service had predicted a normal to wet monsoon after a bone-dry winter, based largely on sea-surface temperatures in the Pacific. But as a global warming trend driven by heat-trapping pollutants pumps energy into the atmosphere, patterns of drought, heat and storm tracks have become harder and harder to predict. So the monsoon has splashed and sputtered, with a week of storms giving way to a week of hot, dry weather – extending the fire season well into the period when fire crews would normally shift to other areas. Fortunately, the extended forecast calls for a chance the monsoon will gust back to life next week.